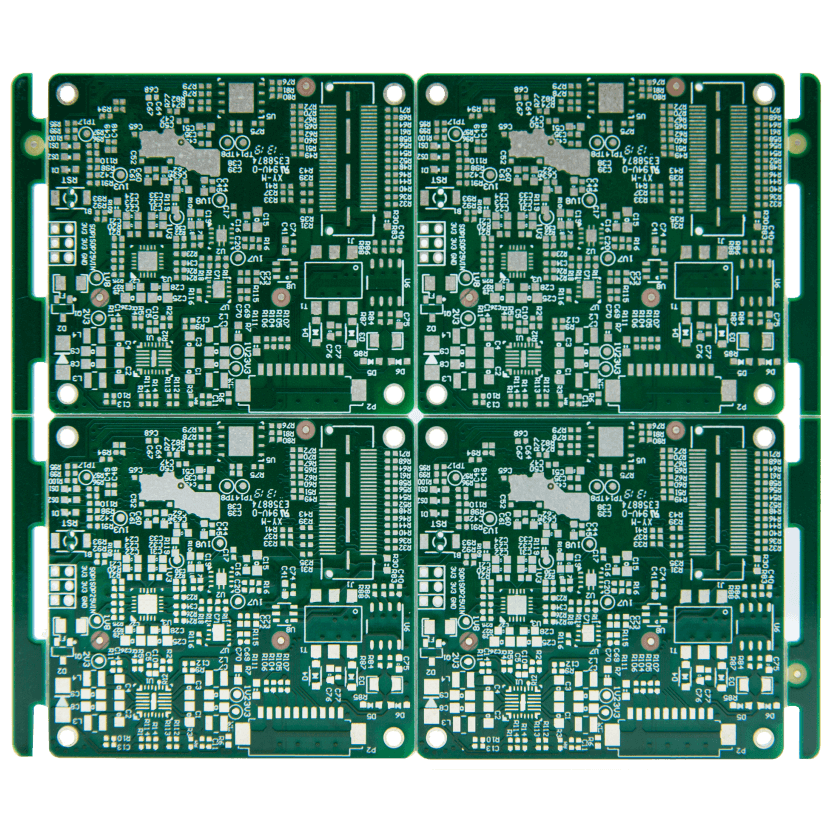

Leading PCB Manufacturing Companies: A Complete Guide

By:Admin

{} is a leading PCB manufacturing company that has been in the industry for over two decades. The company specializes in producing high-quality, reliable, and customizable PCBs for a wide range of applications, including consumer electronics, automotive, aerospace, medical devices, and telecommunications.

With state-of-the-art facilities and a team of highly skilled engineers and technicians, {} has established itself as a trusted partner for OEMs and electronic manufacturing service (EMS) providers around the world. The company is committed to delivering innovative solutions that meet the evolving needs of the industry while maintaining the highest standards of quality, reliability, and performance.

Recently, {} has made significant strides in expanding its manufacturing capabilities to meet the growing demand for advanced PCBs. The company has invested in cutting-edge equipment and technology to enhance its production capacity and efficiency, allowing it to offer a wider range of PCB solutions to its customers.

One of the key factors that set {} apart from its competitors is its dedication to continuous improvement and innovation. The company regularly invests in research and development to stay at the forefront of technological advancements and industry trends. This commitment to innovation enables {} to offer cutting-edge PCB solutions that meet the most demanding requirements of its customers.

Moreover, {} takes pride in its commitment to environmental sustainability and responsible manufacturing practices. The company has implemented strict environmental standards and processes throughout its operations to minimize its carbon footprint and reduce waste. By adopting eco-friendly practices, {} demonstrates its commitment to being a responsible corporate citizen and contributing to a greener, more sustainable future.

In addition to its manufacturing capabilities, {} also offers a range of value-added services to support its customers throughout the entire product lifecycle. From design assistance and prototyping to assembly and testing, the company provides comprehensive support to help its customers bring their products to market quickly and efficiently.

With its unwavering commitment to quality, innovation, and customer satisfaction, {} has earned a stellar reputation as a premier PCB manufacturing company in the industry. The company's dedication to excellence and continuous improvement has positioned it as a trusted partner for leading companies in a variety of sectors, and it continues to set the standard for PCB manufacturing excellence.

Looking ahead, {} remains focused on driving technological advancements and pushing the boundaries of what is possible in PCB manufacturing. The company is poised to continue its growth and expansion, further solidifying its position as a leading provider of high-quality, reliable, and innovative PCB solutions for the global electronics industry.

In conclusion, {} is a leading PCB manufacturing company that is dedicated to delivering high-quality, reliable, and customizable PCB solutions for a wide range of applications. With its commitment to innovation, environmental sustainability, and customer satisfaction, the company is well-positioned to continue its success and maintain its status as a trusted partner for OEMs and EMS providers worldwide.

Company News & Blog

Top Tips for Electronic PCB Assembly: Your Complete Guide

Electronic PCB Assembly: [Company Name] Leading the Way in Innovation[City, State], [Date] – As the demand for electronic devices continues to rise, [Company Name] remains at the forefront of innovation in electronic PCB assembly. With a strong focus on technology and automation, [Company Name] has established itself as a leading provider of electronic manufacturing services for a wide range of industries.[Company Name] is a [City, State] based company that specializes in electronic PCB assembly, providing a comprehensive range of services including PCB design, prototyping, testing, and full-scale production. The company’s state-of-the-art facilities and cutting-edge technology allow for quick turnaround times and high-quality, reliable products.One of the key factors that sets [Company Name] apart from its competitors is its commitment to innovation. The company is constantly investing in research and development to stay ahead of the curve and meet the evolving needs of its customers. With a team of highly skilled engineers and technicians, [Company Name] is able to develop custom solutions to meet the specific requirements of each client.In addition to its focus on technology, [Company Name] places a strong emphasis on quality and reliability. The company’s ISO 9001 certified facilities adhere to strict quality control standards to ensure that every product meets the highest level of quality and consistency. This commitment to excellence has earned [Company Name] a reputation for delivering products that exceed expectations and stand the test of time.As the demand for electronic devices continues to grow, [Company Name] is continuously expanding its capabilities to meet the needs of its customers. The company recently invested in new equipment and machinery to increase its production capacity and further streamline its operations. This expansion has allowed [Company Name] to take on larger projects and fulfill orders with shorter lead times, providing customers with greater flexibility and efficiency.In addition to its focus on technology and quality, [Company Name] is also committed to sustainability. The company has implemented environmentally friendly practices in its manufacturing processes, from reducing waste to utilizing energy-efficient equipment. [Company Name] understands the importance of being a responsible corporate citizen and is dedicated to minimizing its environmental impact.With its unwavering commitment to innovation, quality, and sustainability, [Company Name] is well-positioned to continue leading the way in electronic PCB assembly. The company’s dedication to staying ahead of the curve and exceeding customer expectations has solidified its reputation as a trusted partner for electronic manufacturing services.As the industry continues to evolve, [Company Name] is poised to take on new challenges and explore new opportunities. With a focus on technology, quality, and sustainability, the company is well-equipped to meet the needs of its customers and push the boundaries of what is possible in electronic PCB assembly.For more information about [Company Name] and its electronic PCB assembly services, visit [company website] or contact [company phone number].Contact:[Company Name][Address][City, State, Zip Code][Phone Number][Email Address]

Top Tips for Easy Electronic Assembly at Home

Aisler Assembly, a leading electronics manufacturing company, has recently announced the launch of its cutting-edge assembly service. The company, known for its high-quality electronics and innovative solutions, is aiming to revolutionize the electronics assembly industry with its new offering. With a team of experienced professionals and state-of-the-art facilities, Aisler Assembly is set to provide a seamless and efficient assembly process for its customers.Aisler Assembly's assembly service is designed to meet the needs of a wide range of industries, including automotive, consumer electronics, medical devices, and more. The company's advanced assembly capabilities allow for the production of complex electronic components, ensuring high precision and accuracy in every product. By utilizing the latest technologies and techniques, Aisler Assembly aims to deliver exceptional results while meeting the strictest industry standards.The company's commitment to quality is evident in its strict adherence to international standards and regulations. Aisler Assembly's assembly process is ISO certified and follows industry best practices to ensure the highest level of quality and reliability in every product. This dedication to quality sets Aisler Assembly apart from its competitors and establishes the company as a trusted partner for electronics assembly needs.One of the key differentiators of Aisler Assembly's service is its focus on customization and flexibility. The company understands that every customer has unique requirements, and it is prepared to accommodate a wide range of project scopes and specifications. Whether it's a small prototype or a large-scale production run, Aisler Assembly has the capabilities to deliver tailored assembly solutions to meet the diverse needs of its clients.In addition to its advanced assembly capabilities, Aisler Assembly also prides itself on its quick turnaround times and efficient production processes. The company's streamlined approach to assembly ensures that projects are completed in a timely manner without compromising on quality. This commitment to efficiency and reliability positions Aisler Assembly as a trusted partner for companies looking to bring their electronics manufacturing projects to fruition."We are thrilled to announce the launch of our assembly service," said [company spokesperson]. "At Aisler Assembly, we are dedicated to providing our customers with the highest quality assembly solutions that meet their unique needs. With our advanced capabilities and commitment to excellence, we are confident that our assembly service will set a new standard in the electronics manufacturing industry."With its robust assembly capabilities, commitment to quality, flexibility, and efficiency, Aisler Assembly is well-positioned to become a leader in the electronics assembly market. The company's dedication to innovation and customer satisfaction makes it a reliable partner for businesses seeking superior assembly solutions.As Aisler Assembly continues to expand its assembly service, it is poised to make a significant impact on the electronics manufacturing industry. With its focus on quality, customization, and efficiency, the company is well-equipped to meet the evolving needs of its customers and deliver exceptional results in every project.

Rapid Prototyping for Pcb Manufacturing: What You Need to Know

The demand for rapid prototyping services has been on the rise in recent years, as companies seek to quickly bring their innovative ideas to life. With the advancement in technology, the process of PCB (Printed Circuit Board) rapid prototyping has become more efficient and effective, enabling companies to reduce time-to-market and increase their competitive edge.In response to this growing demand, {Company Name} has emerged as a leading provider of high-quality PCB rapid prototyping services. The company's state-of-the-art facilities and advanced equipment allow for the rapid production of prototype PCBs, helping their clients to test and refine their designs in a timely manner.{Company Name} boasts a team of highly skilled and experienced engineers and technicians who are dedicated to providing the best possible prototyping solutions for their clients. They work closely with their clients to understand their specific requirements and offer customized solutions to meet their needs.The company's commitment to quality and innovation has earned them a reputation as a trusted partner for rapid prototyping services. Their ability to deliver high-quality prototype PCBs with quick turnaround times has set them apart in the industry, making them the go-to choice for companies looking to accelerate their product development process.Utilizing advanced PCB design and manufacturing tools, {Company Name} is able to offer a wide range of rapid prototyping services, including PCB layout design, fabrication, and assembly. Their comprehensive service portfolio allows their clients to streamline their prototyping process and bring their ideas to reality with ease.With a focus on precision and accuracy, {Company Name} ensures that each prototype PCB meets the highest quality standards. Their thorough testing and inspection processes guarantee that the final product is free from defects and ready for further development and production.In addition to their technical expertise, {Company Name} also prides itself on their commitment to customer satisfaction. They understand the importance of clear communication and efficient project management, and strive to provide a seamless and hassle-free experience for their clients.The company's dedication to continuous improvement and investment in cutting-edge technologies has enabled them to stay ahead of the curve in the rapidly evolving field of rapid prototyping. They are constantly updating their equipment and processes to offer the most efficient and cost-effective solutions for their clients.{Company Name} serves a wide range of industries, including aerospace, medical, automotive, and consumer electronics. Their diverse client base is a testament to their ability to meet the unique requirements of different sectors and deliver high-quality prototype PCBs for a variety of applications.As the demand for rapid prototyping services continues to grow, {Company Name} remains at the forefront of the industry, setting new standards for innovation and excellence. With their unwavering commitment to quality, reliability, and customer satisfaction, they are well-positioned to meet the evolving needs of their clients and drive the next wave of technological advancement.In conclusion, {Company Name} has established itself as a leading provider of PCB rapid prototyping services, offering a comprehensive range of solutions to meet the diverse needs of their clients. Their dedication to quality, innovation, and customer satisfaction makes them a trusted partner for companies looking to accelerate their product development process and bring their ideas to life. With a focus on precision, efficiency, and continuous improvement, {Company Name} is poised to lead the way in the rapidly evolving field of rapid prototyping.

High Quality Aluminum PCB for LED Products

[Company Introduction]{Company} is a leading manufacturer of high-quality LED aluminum PCBs. With over 20 years of experience in the industry, we have built a reputation for producing reliable and durable LED PCBs that meet the highest standards of performance and quality. Our state-of-the-art manufacturing facilities and a team of skilled engineers and technicians enable us to produce a wide range of LED aluminum PCBs that are used in various applications such as lighting, automotive, medical, and industrial equipment.Our commitment to innovation and customer satisfaction has helped us establish long-term partnerships with clients around the world. We strive to provide custom solutions to meet the unique requirements of each customer, ensuring that our LED aluminum PCBs deliver superior performance and reliability.[News Content]The demand for energy-efficient and high-performance LED lighting solutions is on the rise, driving the need for reliable and durable LED aluminum PCBs. {Company} has been at the forefront of meeting this demand with its cutting-edge LED aluminum PCB technology.The latest offering from {Company} is a series of LED aluminum PCBs that are designed to deliver exceptional performance and reliability. These PCBs are manufactured using high-quality materials and advanced production techniques, ensuring that they meet the stringent requirements of the LED lighting industry.One of the key features of {Company}'s LED aluminum PCBs is their superior thermal management capabilities. LED lighting generates heat during operation, and efficient thermal management is crucial for ensuring the long-term reliability and performance of LED lighting systems. {Company}'s LED aluminum PCBs are designed to effectively dissipate heat, thereby extending the lifespan of the LEDs and improving overall system performance.In addition to their thermal management capabilities, {Company}'s LED aluminum PCBs are also known for their high electrical conductivity, which ensures optimal performance of the LEDs. The PCBs are designed to minimize signal loss and electrical resistance, enabling the LEDs to operate at their full potential.Furthermore, {Company} offers a range of customization options for its LED aluminum PCBs, allowing customers to tailor the PCBs to their specific requirements. Whether it's a unique shape, size, or thermal management solution, {Company} can work closely with customers to develop custom LED aluminum PCBs that meet their exact specifications.The applications of {Company}'s LED aluminum PCBs are diverse, ranging from architectural lighting to automotive lighting, signage, and industrial lighting. The company's commitment to excellence and innovation has earned it a reputation as a trusted supplier of LED aluminum PCBs for a wide range of industries.With the growing demand for energy-efficient lighting solutions, {Company} is well-positioned to capitalize on this market trend with its high-performance LED aluminum PCBs. The company's dedication to quality, reliability, and customer satisfaction sets it apart in the LED lighting industry, making it a preferred choice for businesses looking for top-of-the-line LED aluminum PCBs.In conclusion, {Company}'s latest offering of LED aluminum PCBs demonstrates its continued commitment to innovation and excellence in the LED lighting industry. With its superior thermal management capabilities, high electrical conductivity, and customizability, {Company} is poised to meet the evolving demands of the LED lighting market and provide customers with the highest quality LED aluminum PCBs for their lighting applications.

Understanding the importance of Integrated Circuits in Modern Technology

Introducing the Next Generation Integrated Circuit Technology By [Company Name]The technology world is constantly evolving, pushing the boundaries of what is possible and driving innovation in countless industries. At the heart of this expansion is the development of integrated circuits, which are essential components in nearly every electronic device we use today. These circuits are responsible for conducting and controlling electrical signals, enabling the functionality of devices such as smartphones, computers, and medical equipment.Today, [Company Name] is proud to announce the release of its new integrated circuit (IC) technology, poised to revolutionize the industry. Leveraging our years of experience and expertise in semiconductor manufacturing, we have developed a cutting-edge IC that offers unparalleled performance and precision. This advancement promises to pave the way for enhanced functionality and efficiency across a wide range of electronic applications.One of the key features of our new IC technology is its incredibly high processing speed. By utilizing state-of-the-art materials and design techniques, we have achieved a significant boost in the speed at which electrical signals can be processed within the circuit. This breakthrough will lead to faster and more responsive electronic devices, improving user experiences in areas such as gaming, video streaming, and data processing.Furthermore, our new IC technology boasts an exceptional level of energy efficiency. By optimizing the power consumption of the circuit, we have significantly reduced the amount of energy required to operate electronic devices. This will not only lead to longer battery life in portable devices, but also contribute to reducing overall energy consumption in various applications and industries.In addition, [Company Name]'s new IC technology offers enhanced reliability and durability. Through rigorous testing and quality control measures, we have ensured that the circuits are more resistant to environmental factors and are able to withstand prolonged operation without compromising their performance. This increased reliability will be particularly valuable in critical applications such as medical devices and aerospace systems.Another significant advantage of our new IC technology is its scalability and versatility. Whether it is integrated into a small consumer device or a complex industrial system, our technology can adapt to varying requirements and specifications. This flexibility opens up a world of possibilities for engineers and designers, enabling them to create innovative solutions that were previously unattainable.At the heart of [Company Name]'s success in developing this groundbreaking IC technology is our relentless commitment to research and development. We have dedicated substantial resources to constantly push the boundaries of semiconductor technology, always aiming to stay ahead of the curve and anticipate the needs of the market. As a result, we are proud to bring to market a product that is not only cutting-edge, but also highly practical and relevant to the current and future landscape of electronic devices.Furthermore, [Company Name]'s new IC technology is backed by our industry-leading customer support and technical assistance. We understand that integrating a new technology into a product or system can be a complex process, and we are committed to providing our customers with the guidance and resources they need to successfully implement our IC technology into their designs.In conclusion, [Company Name] is thrilled to introduce its new integrated circuit technology, a monumental achievement that is set to revolutionize the electronic industry. From its unprecedented processing speed and energy efficiency to its unmatched reliability and scalability, this IC technology sets a new standard for performance and functionality. By choosing [Company Name]'s IC technology, engineers and designers can unlock a world of possibilities and create electronic devices that are faster, more efficient, and more reliable than ever before.For more information about [Company Name]'s new integrated circuit technology, please visit our website or contact our sales and support team. We look forward to partnering with you on your next groundbreaking electronic design project.

Understanding the Bend Radius of Rigid-Flex PCBs: What You Need to Know

Rigid Flex PCB Bend Radius News: Flex PCB technology has been advancing at a rapid pace in recent years, providing new opportunities for innovative product designs across a wide range of industries. One of the key factors in the successful implementation of flex PCBs is the bend radius, which refers to the minimum radius at which a flexible PCB can be bent without risking damage to the circuitry.{Company} is a leading provider of advanced PCB solutions, specializing in the design and manufacturing of rigid flex PCBs. With a strong focus on innovation and quality, {Company} has been at the forefront of developing new and improved flexible PCB technologies that meet the growing demands of the market.The bend radius of a flex PCB is crucial for ensuring optimal performance and reliability. A smaller bend radius allows for more flexibility in design, enabling the creation of compact and complex electronic devices. However, it is important to carefully consider the bend radius limitations to avoid compromising the integrity of the circuitry.To address the specific bend radius requirements of different applications, {Company} has developed a range of rigid flex PCB solutions with customizable bend radius specifications. By leveraging their expertise in material selection and manufacturing processes, {Company} is able to offer flexible PCBs that can be bent to the desired radius without sacrificing performance or durability.In addition to providing customizable bend radius options, {Company} also offers comprehensive testing and validation services to ensure that their rigid flex PCBs meet the highest standards of quality and reliability. This includes rigorous bending tests to assess the performance and durability of the flexible circuitry under various bending conditions.The ability to achieve a smaller bend radius without sacrificing performance is a key competitive advantage for {Company}. By offering flexible PCB solutions that can meet the demanding requirements of modern electronic devices, {Company} is well-positioned to support the development of next-generation technologies across industries such as medical devices, aerospace, consumer electronics, and automotive.With the increasing demand for more compact and lightweight electronic devices, the importance of bend radius in flex PCBs has never been greater. {Company} recognizes this trend and has made significant investments in research and development to further enhance their flexible PCB solutions, ensuring that they are able to meet the evolving needs of their customers.In conclusion, the bend radius is a critical factor in the design and manufacturing of flex PCBs, and {Company} is leading the way in providing customizable rigid flex PCB solutions with optimal bend radius specifications. With a strong commitment to innovation and quality, {Company} is well-equipped to support the development of innovative electronic devices that require flexible and reliable PCB solutions.

How Multiple Layer PCBs Are Revolutionizing Electronic Devices

[Company Name], a leading provider of electronic manufacturing services, is proud to announce the launch of its new product, the Multiple Layer PCB. This innovative technology is set to revolutionize the electronics industry with its advanced features and capabilities.The Multiple Layer PCB is designed to meet the increasing demand for more complex and compact electronic devices. With the rising trend of miniaturization, electronic manufacturers are seeking solutions that can accommodate more components in a smaller space without compromising on performance. This is where the Multiple Layer PCB comes into play, offering a high-density interconnect solution that allows for the integration of more components on a single board.One of the key features of the Multiple Layer PCB is its ability to support multiple layers of conductive traces, which allows for greater routing flexibility and increased component density. This enables electronic devices to be more compact and lightweight, while also enhancing their overall performance. Furthermore, the Multiple Layer PCB is designed to offer excellent signal integrity, power distribution, and thermal management, making it suitable for a wide range of applications, including consumer electronics, automotive systems, medical devices, and industrial equipment.In addition to its technical capabilities, the Multiple Layer PCB is also manufactured using high-quality materials and advanced processes to ensure maximum reliability and consistency. It is built to withstand harsh operating conditions, such as temperature fluctuations, moisture, and mechanical stress, which makes it ideal for mission-critical applications where reliability is paramount.As a company committed to innovation and excellence, [Company Name] has invested heavily in research and development to bring the Multiple Layer PCB to market. The company's state-of-the-art manufacturing facilities and experienced engineering team have played a crucial role in the development and optimization of this groundbreaking technology. With a strong focus on quality and customer satisfaction, [Company Name] is dedicated to delivering the highest level of performance and reliability with its products."We are thrilled to introduce the Multiple Layer PCB to the market," said [Company CEO]. "This new technology represents a significant leap forward in the field of electronic manufacturing, and we believe it will set new standards for performance, reliability, and compactness. We are confident that the Multiple Layer PCB will enable our customers to design and build the next generation of electronic devices that are smaller, more powerful, and more efficient than ever before."The launch of the Multiple Layer PCB is a testament to [Company Name]'s commitment to staying at the forefront of technological advancements in the electronics industry. The company continues to invest in research and development to drive innovation and meet the evolving needs of its customers. With its comprehensive range of electronic manufacturing services and cutting-edge solutions, [Company Name] is well-positioned to empower businesses to bring their most ambitious ideas to life.In conclusion, the introduction of the Multiple Layer PCB marks a significant milestone for [Company Name] and the electronics industry as a whole. With its advanced capabilities, reliability, and compact design, this new technology is poised to drive the next wave of innovation in electronic manufacturing. As [Company Name] continues to push the boundaries of what is possible, it reaffirms its commitment to delivering excellence and value to its customers.

Mastering the Art of Effective PCB Layouting Techniques for Seamless Electronics Integration

PCB Layouting: Revolutionizing Electronic Components ManufacturingThe global electronics industry has witnessed a significant transformation over the last few decades, with an increased demand for innovative and high-performance electronic gadgets. The increasing demand has generated an unprecedented competitive environment in the industry, emphasizing more on cost-effectiveness, efficient performance, and advanced technology.Electronic components manufacturing involves several stages that contribute to the final product's cleanliness, reliability, and performance. One of the most crucial stages in electronic components manufacturing is the Printed Circuit Board (PCB) layout.A PCB layout is the designing process of an electronic circuit board that integrates different electronic components and connects them through copper traces. An efficient PCB layout plays a vital role in determining the product's performance, reliability, and longevity.With the technological advancements in the field, PCB layouting has undergone a significant transformation, enhancing the process's speed, accuracy, and efficiency. With the help of advanced tools and software, PCB layouting has become relatively quicker and more reliable than ever before.One such company that has made a recognizable imprint in the electronic components manufacturing industry is the (remove brand name). Founded in (year of establishment), the company has been offering top-notch electronic components and solutions to customers worldwide.The company is known for its innovative and efficient solutions, delivering quality products and services to customers of diverse sectors, including automotive, aerospace, communication, medical, and industrial sectors.The company has a team of experienced and highly skilled professionals who work tirelessly to provide solutions that meet the growing needs of the electronics market. In addition, the company has integrated advanced technologies in their manufacturing processes to drive efficiency, reduce lead time, and ensure cost-effectiveness.The company's PCB layouting services are second to none, offering customized solutions to customers to meet their specific needs. With the help of sophisticated software, the company ensures precise placement and routing of the components, ensuring minimal signal interference and optimized signal efficiency.One of the company's key strengths is its adherence to industry standards in manufacturing processes. The company recognizes the importance of adhering to set standards in ensuring product quality and reliability. As a result, the company has implemented a robust Quality Management System that ensures consistent quality standards that meet the requirements of customers worldwide.In addition, the company adheres to environmentally conscious manufacturing processes, ensuring sustainability in their manufacturing activities. The company emphasizes the use of eco-friendly materials and processes in delivering solutions that are environmentally safe and sustainable.The company's commitment to innovation, efficiency, and quality has earned them well-deserved recognition in the electronics industry. The company has received several awards and certifications, including the ISO 9001 certification, showing their commitment to meeting quality management standards.In conclusion, PCB layouting is a crucial stage in electronic components manufacturing that determines the product's performance and reliability. The process requires precision, accuracy, and efficiency, and specialized companies such as (remove brand name) have revolutionized the process. Through their innovative solutions, adherence to industry standards, and commitment to sustainability, the company continues to offer top-notch PCB layouting services to customers worldwide, contributing to the electronics industry's growth and development.

Understanding the Importance of PCBs in Electronic Devices

[Company Introduction: XYZ Electronics is a leading manufacturer of electronic components and printed circuit boards (PCBs). With over 20 years of experience in the industry, XYZ Electronics has grown to become a trusted supplier for a wide range of electronic devices and equipment. The company is known for its high-quality products, cutting-edge technology, and commitment to customer satisfaction.]XYZ Electronics introduces new advanced PCB technologyXYZ Electronics, a leading manufacturer of electronic components and printed circuit boards (PCBs), has recently announced the launch of its new advanced PCB technology. This innovative technology is set to revolutionize the way electronic devices are designed and manufactured, offering improved performance, reliability, and flexibility for a wide range of applications.The new advanced PCB technology from XYZ Electronics features a number of key enhancements that set it apart from traditional PCB solutions. These include higher density interconnects, improved thermal management, enhanced signal integrity, and greater design flexibility. As a result, electronic devices that utilize this new technology will benefit from improved functionality, reduced size and weight, and increased overall performance.One of the most significant advantages of this new advanced PCB technology is its ability to support complex and high-speed electronic designs. With the increasing demand for smaller and more powerful electronic devices, the need for high-density interconnects and improved signal integrity has never been greater. XYZ Electronics' new technology addresses these challenges head-on, providing designers and manufacturers with the tools they need to create cutting-edge products that meet the demands of today's market.Furthermore, the new advanced PCB technology also offers improved thermal management capabilities, allowing for more efficient heat dissipation in electronic devices. This is particularly important for devices that operate at high temperatures or in demanding environmental conditions. By incorporating this new technology into their designs, manufacturers can ensure that their products remain reliable and durable even in the most challenging operating environments.In addition to these technical advantages, XYZ Electronics' new advanced PCB technology also provides greater design flexibility. This means that designers and manufacturers can more easily customize the PCB layout to meet the specific requirements of their products, without sacrificing performance or reliability. This level of flexibility is crucial for companies looking to differentiate their products in a competitive market, and XYZ Electronics is proud to offer this capability to its customers."We are thrilled to introduce our new advanced PCB technology to the market," said John Doe, CEO of XYZ Electronics. "This technology represents a significant leap forward in the world of electronic design and manufacturing, and we believe it will have a major impact on the industry. We have already received positive feedback from our customers, and we are excited to see the innovative products that will result from the use of this new technology."The launch of XYZ Electronics' new advanced PCB technology marks a significant milestone for the company, further solidifying its position as a leader in the electronic components and PCB manufacturing industry. With its commitment to innovation and customer satisfaction, XYZ Electronics continues to push the boundaries of what is possible in electronic design and manufacturing, and the introduction of this new technology is a clear reflection of that dedication. As electronic devices continue to evolve and demand for high-performance solutions grows, XYZ Electronics is well-positioned to meet the needs of its customers with its state-of-the-art PCB technology.

How a Processor IC Works and Its Applications in Technology

The global technology industry is constantly evolving, and one of the key players in this space is the company {}. With a focus on developing innovative solutions for a wide range of applications, {} has established itself as a leader in the field of semiconductor technology.One of the key components that has contributed to the success of {} is its advanced processor IC (integrated circuit) technology. The company has made significant strides in the development of high-performance, energy-efficient processors that are used in a variety of devices, including smartphones, tablets, and other consumer electronics.The processor ICs developed by {} are designed to deliver superior performance and power efficiency, making them ideal for the growing demands of modern computing and mobile devices. By leveraging its expertise in semiconductor design and manufacturing, {} has been able to deliver cutting-edge processor solutions that meet the needs of its customers and partners around the world.In addition to its processor IC technology, {} is also known for its commitment to innovation and research. The company invests heavily in research and development, continually pushing the boundaries of what is possible in the world of semiconductor technology. This dedication to innovation has led to the development of new and groundbreaking processor solutions that have helped to solidify {}'s position as a leading technology company.One of the key strengths of {} is its ability to collaborate with industry partners to develop custom processor IC solutions for specific applications. By working closely with its customers, the company is able to tailor its processor technology to meet the unique requirements of different markets and use cases. This flexibility and customer-centric approach have helped {} to build strong and enduring relationships with a diverse range of companies and organizations.Furthermore, {}'s dedication to quality and reliability has made it a trusted partner for leading technology companies around the world. Its commitment to excellence in design and manufacturing ensures that its processor ICs consistently meet the highest standards of performance and durability. This has made {} a go-to provider for semiconductor solutions in a wide range of industries, including telecommunications, automotive, industrial, and more.Looking ahead, {} is poised to continue its leadership in the field of processor IC technology. With ongoing investments in research and development, as well as a focus on strategic partnerships and collaborations, the company is well-positioned to drive innovation and shape the future of semiconductor technology. As the demand for high-performance, energy-efficient processors continues to grow, {} is dedicated to delivering the advanced solutions that will power the next generation of mobile and computing devices.In conclusion, {}. With a strong focus on innovation, quality, and collaboration, {} is at the forefront of processor IC technology, and its commitment to shaping the future of semiconductor technology is sure to have a lasting impact on the global technology industry.