- Home

- Blog

- Mastering the Art of Effective PCB Layouting Techniques for Seamless Electronics Integration

Mastering the Art of Effective PCB Layouting Techniques for Seamless Electronics Integration

By:Admin

The global electronics industry has witnessed a significant transformation over the last few decades, with an increased demand for innovative and high-performance electronic gadgets. The increasing demand has generated an unprecedented competitive environment in the industry, emphasizing more on cost-effectiveness, efficient performance, and advanced technology.

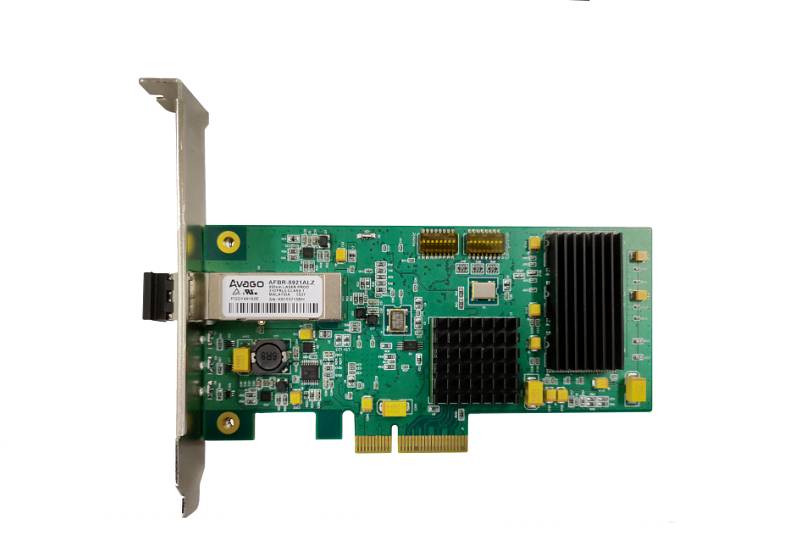

Electronic components manufacturing involves several stages that contribute to the final product's cleanliness, reliability, and performance. One of the most crucial stages in electronic components manufacturing is the Printed Circuit Board (PCB) layout.

A PCB layout is the designing process of an electronic circuit board that integrates different electronic components and connects them through copper traces. An efficient PCB layout plays a vital role in determining the product's performance, reliability, and longevity.

With the technological advancements in the field, PCB layouting has undergone a significant transformation, enhancing the process's speed, accuracy, and efficiency. With the help of advanced tools and software, PCB layouting has become relatively quicker and more reliable than ever before.

One such company that has made a recognizable imprint in the electronic components manufacturing industry is the (remove brand name). Founded in (year of establishment), the company has been offering top-notch electronic components and solutions to customers worldwide.

The company is known for its innovative and efficient solutions, delivering quality products and services to customers of diverse sectors, including automotive, aerospace, communication, medical, and industrial sectors.

The company has a team of experienced and highly skilled professionals who work tirelessly to provide solutions that meet the growing needs of the electronics market. In addition, the company has integrated advanced technologies in their manufacturing processes to drive efficiency, reduce lead time, and ensure cost-effectiveness.

The company's PCB layouting services are second to none, offering customized solutions to customers to meet their specific needs. With the help of sophisticated software, the company ensures precise placement and routing of the components, ensuring minimal signal interference and optimized signal efficiency.

One of the company's key strengths is its adherence to industry standards in manufacturing processes. The company recognizes the importance of adhering to set standards in ensuring product quality and reliability. As a result, the company has implemented a robust Quality Management System that ensures consistent quality standards that meet the requirements of customers worldwide.

In addition, the company adheres to environmentally conscious manufacturing processes, ensuring sustainability in their manufacturing activities. The company emphasizes the use of eco-friendly materials and processes in delivering solutions that are environmentally safe and sustainable.

The company's commitment to innovation, efficiency, and quality has earned them well-deserved recognition in the electronics industry. The company has received several awards and certifications, including the ISO 9001 certification, showing their commitment to meeting quality management standards.

In conclusion, PCB layouting is a crucial stage in electronic components manufacturing that determines the product's performance and reliability. The process requires precision, accuracy, and efficiency, and specialized companies such as (remove brand name) have revolutionized the process. Through their innovative solutions, adherence to industry standards, and commitment to sustainability, the company continues to offer top-notch PCB layouting services to customers worldwide, contributing to the electronics industry's growth and development.

Company News & Blog

Exploring the Role and Advancements of Printed Wiring Boards

article:As our world becomes increasingly reliant on technology, Printed Wiring Boards (PWBs) are playing a vital role in powering our devices and infrastructure. Headquartered in Japan, {} is a leading producer of PWBs that has been at the forefront of this industry for over 90 years. In this article, we will explore the history of this company, as well as the innovation and technology that drives its success.Founded in 1926, {} began as a small producer of electronic components in Japan. Over the years, the company continued to expand and innovate, eventually becoming a leading producer of PWBs. Today, their products are used in a wide range of industries, from transportation and healthcare to telecommunications and aerospace.One of the keys to {}'s success has been their commitment to research and development. The company has a team of over 1,000 engineers and scientists who are focused on creating new and innovative products. In recent years, {} has invested heavily in developing PWBs that are smaller, more durable, and can handle higher levels of power. This has allowed their products to be used in more advanced technologies, such as 5G networks and electric vehicles.Another area where {} has shown leadership is in sustainability. The company has implemented a number of initiatives to reduce their environmental impact, such as using recycled materials in their production process and developing PWBs with low power consumption. Furthermore, {} is committed to ethical business practices and has been recognized for their efforts in ensuring fair labor standards and working conditions.In addition to their commitment to innovation and sustainability, {} has also earned a strong reputation for quality. Their products undergo rigorous testing and certification processes to ensure they meet the highest industry standards. Furthermore, {} has implemented a number of quality control measures throughout their production process, which has resulted in a very low defect rate.Finally, {} has a global presence with factories and sales offices located around the world. This allows them to serve a diverse range of customers and ensure that their products are available to customers wherever they are needed. Moreover, their team of experts is able to provide support and technical assistance to customers in order to ensure that they get the most out of their products.In conclusion, Printed Wiring Boards are a vital component of the modern world and {} is a leading producer in this industry. Through their commitment to innovation, sustainability, quality, and customer support, {} has earned a reputation for excellence and reliability. As technology continues to advance, we can expect {} to remain at the forefront of this industry, driving progress and shaping the future.

Efficient SMT Assembly Process: Streamlining Production for Optimal Results

Smt Assembly Process Revolutionizes Electronics Manufacturing IndustryIn an industry that is constantly evolving, companies are always seeking new ways to improve their manufacturing processes to stay ahead of the competition. One such company, based in {}, has recently introduced an innovative method called Surface Mount Technology (SMT) assembly process. This groundbreaking technology is set to revolutionize the electronics manufacturing industry.With the SMT assembly process, components are mounted directly onto the surface of a printed circuit board (PCB). This method eliminates the need for through-hole technology, where components are mounted by inserting leads into drilled holes on the board. Instead, SMT components are soldered onto the board using specialized machines, which saves production time and reduces costs.This new process has caught the attention of several companies in the electronics manufacturing industry due to its numerous advantages. One major benefit is the increased precision and accuracy achieved through SMT assembly. The components are placed precisely in predetermined locations, ensuring the reliability and functionality of the final product. This level of precision was previously difficult to achieve with through-hole technology.Furthermore, the SMT assembly process allows for miniaturization of electronic devices. As SMT components are smaller than their through-hole counterparts, companies can design and manufacture smaller, more compact electronic products. This is especially important in industries such as consumer electronics and medical devices, where portability and size are significant factors.Moreover, the SMT assembly process enables a higher degree of automation in production. By utilizing specialized machines, companies can streamline their manufacturing processes and increase production capacity. This automation not only improves efficiency but also reduces the potential for human error, leading to higher quality products.The environmental impact of electronic manufacturing is another critical consideration in today's world. Fortunately, the SMT assembly process is more environmentally friendly compared to through-hole technology. SMT components consume fewer materials, generate less waste, and use lead-free solders. This reduction in waste and hazardous materials contributes to a greener manufacturing process, aligning with global environmental standards.With numerous advantages in speed, precision, miniaturization, automation, and environmental impact, it's no wonder that more and more companies are adopting the SMT assembly process. One such company leading the way in implementing this revolutionary method is {}. Combining cutting-edge technology with their deep industry experience, they have successfully transformed the manufacturing process for electronics.{} is committed to providing the highest quality SMT assembly services to their clients. They understand the importance of staying at the forefront of technology in a rapidly evolving industry. With state-of-the-art equipment and a team of skilled professionals, they ensure that every product manufactured using the SMT assembly process meets the highest standards of quality and reliability.The company's dedication to customer satisfaction is unparalleled. They work closely with their clients to understand their unique requirements and provide tailored solutions that meet their specific needs. From component sourcing and PCB design to assembly and testing, {} offers a comprehensive range of services, all utilizing the innovative SMT assembly process.As the electronics manufacturing industry continues to grow and evolve, adopting cutting-edge technologies like the SMT assembly process is vital for remaining competitive. With its numerous advantages, this revolutionary method is set to transform the industry, enabling companies to produce higher quality, more compact, and environmentally friendly electronic devices.In a world where technology is advancing at an unprecedented pace, companies must adapt and embrace innovation to stay ahead. With the introduction of the SMT assembly process, {} is leading the charge in revolutionizing the electronics manufacturing industry, paving the way for a more efficient, precise, and sustainable future.

Breakthrough in Computer Technology: Researchers Develop Groundbreaking Chip Cracking Technique

[Related Company Information][Introduction]Chip Cracking: Shaping the Future of Semiconductor Technology[City Name], [Date] - In an era where technological innovations are at the forefront of global progress, the field of semiconductor technology stands as a vital pillar of the modern world. Pioneering advancements in this domain, [Company Name] has emerged as a leading player, revolutionizing the industry with its groundbreaking chip cracking techniques. Committed to pushing boundaries, the company is bringing forth a transformative wave, spearheading advancements that are set to redefine the potential of semiconductor technology.[Company Name] prides itself on a rich legacy of discovery and technological excellence. With a team of highly skilled engineers and industry experts, the company has consistently driven innovation, delivering cutting-edge solutions to meet the ever-evolving demands of the semiconductor market. Armed with an unwavering commitment to quality and a determination to make a lasting impact, [Company Name] has established itself as a trusted partner to businesses worldwide.One of the key driving forces behind [Company Name]'s success is its groundbreaking chip cracking technology. Their patented method enables the extraction of vital data from microchips, which was previously inaccessible. Leveraging this technique, the company has achieved unprecedented breakthroughs in multiple sectors, including aerospace, healthcare, and automotive industries. By unveiling the hidden potential within microchips, [Company Name] is empowering other companies to unlock new realms of possibilities and propel their growth.The application of chip cracking technology is far-reaching, with implications that go beyond traditional boundaries. In the healthcare sector, for instance, this innovative approach has paved the way for significant advancements in medical devices. By gaining access to comprehensive data stored within microchips, healthcare professionals can develop more accurate diagnostics, personalized treatment plans, and enhanced monitoring systems. This breakthrough not only improves patient care but also augments the capabilities of medical practitioners, enabling them to make more informed decisions.In the aerospace industry, chip cracking technology has revolutionized aircraft manufacturing and maintenance processes. By harnessing the power of microchip data, [Company Name] has allowed aerospace companies to mitigate risks, increase operational efficiency, and enhance passenger safety. From predicting equipment lifespan to optimizing fuel consumption, chip cracking has become a critical tool for aviation industry leaders to streamline operations and drive sustainable growth.Furthermore, chip cracking technology is quickly gaining momentum in the automotive sector, setting the stage for the future of autonomous driving. By decoding data from microchips embedded in cutting-edge vehicle systems, [Company Name] is paving the way for advanced driver-assistance systems (ADAS) and autonomous driving capabilities. This breakthrough not only promises a safer and more efficient transportation landscape but also accelerates the realization of a fully connected and autonomous future.[Company Name]'s chip cracking capabilities are backed by a commitment to ethical practices and stringent quality standards. Adhering to a rigorous code of conduct, the company ensures that data extraction is performed with utmost care, while respecting the intellectual property rights and confidentiality needs of their clients. This approach has earned [Company Name] a reputation for trustworthiness and integrity within the industry, cementing its position as a favored partner for businesses looking to leverage the power of chip cracking technology.As the demand for semiconductor technology continues to soar, [Company Name] remains steadfast in its commitment to innovation. With a focus on research and development, the company is continually refining and expanding its chip cracking techniques, pushing the boundaries of what is possible in the world of microchip data extraction. As a result, [Company Name] is poised to shape the future of semiconductor technology, driving further growth and advancements in various industries worldwide.In an increasingly interconnected world, where the potential for semiconductor technology is virtually limitless, [Company Name] provides a glimpse into what is attainable through chip cracking. With a vision to empower businesses and industries alike, the company is reshaping the landscape of modern technology, marking the beginning of a new era in semiconductor innovation.[Company Name]'s relentless pursuit of excellence combined with their revolutionary chip cracking capabilities positions them as a leading force, propelling the future of the semiconductor industry into unprecedented realms of possibility. With passion, dedication, and a commitment to leaving a lasting impact, the journey undertaken by [Company Name] signifies a monumental leap towards a more advanced, interconnected, and transformative world.

Expert PCB Manufacturing Solutions in the Bay Area" becomes "Top-rated PCB Manufacturing in the Bay Area

Title: Pioneering PCB Manufacturing in the Bay Area Revolutionizes Electronic IndustryIntroduction:In the heart of the innovation hub that is the Bay Area, a leading manufacturer has emerged to disrupt the electronic industry. Through their cutting-edge facilities and commitment to quality, this company has quickly become a game-changer in the world of printed circuit board (PCB) manufacturing. With an unwavering dedication to innovation and customer satisfaction, this visionary manufacturer is establishing itself as a top-tier provider of PCB solutions.Body:1. The Bay Area's Thriving Electronics Landscape:The Bay Area has long been known as a hotbed for technology and innovation, with countless startups and established companies constantly pushing boundaries to create groundbreaking products. With the rise of Internet of Things (IoT) devices, wearables, autonomous vehicles, and advanced medical equipment, the demand for high-quality PCBs has skyrocketed. Recognizing this growth potential, our featured manufacturer entered the scene with a mission to fulfill the increasing demand for innovative PCB solutions.2. Advanced Manufacturing Facilities:The company boasts a state-of-the-art manufacturing facility in the heart of the Bay Area, equipped with cutting-edge machinery and technology. Committed to staying at the forefront of industry advancements, they continually invest in new equipment and software to ensure the highest level of precision, efficiency, and quality in their PCB manufacturing process.3. Embracing Industry Standards:Compliance with industry standards is paramount for any PCB manufacturer. This company exceeds expectations by adhering to stringent international standards, including ISO 9001, ISO 14001, and IPC Class 3. By maintaining these certifications, they ensure the manufacturing of PCBs that meet the highest quality and reliability standards.4. Emphasis on Research and Development:Innovation is the lifeblood of this pioneering manufacturer. To stay ahead of the curve, they place a strong emphasis on research and development, actively collaborating with industry partners and academic institutions to drive forward-thinking solutions. By fostering a culture of innovation and creativity, they continuously push the boundaries of PCB manufacturing, offering cutting-edge solutions to their customers.5. Diverse Product Range:With a customer-centric approach, this PCB manufacturer offers a diverse range of products to cater to various industries such as aerospace, automotive, consumer electronics, telecommunications, medical, and more. Whether it's single-sided, double-sided, flexible, or rigid-flex PCBs, they have the capabilities to provide tailored solutions to meet clients' specific requirements.6. Seamless Customer Experience:Understanding the importance of exceptional customer service, this manufacturer takes pride in offering a seamless experience from start to finish. From initial design consultation to final delivery, they are committed to providing timely communication, personalized attention, and technical guidance to ensure each client's unique needs are met.7. Eco-Friendly Practices:As responsible corporate citizens, the company places a strong emphasis on sustainability. They promote eco-friendly practices by optimizing production processes to minimize waste, recycling materials whenever possible, and reducing environmental impact. Their commitment to sustainability extends beyond manufacturing, ensuring that PCBs are produced ethically and responsibly.Conclusion:In the dynamic landscape of the Bay Area, PCB manufacturing has taken a significant leap forward with this visionary company's innovative approach. Their state-of-the-art manufacturing facilities, commitment to quality and industry standards, focus on research and development, diverse product range, seamless customer experience, and eco-friendly practices distinguish them as trailblazers. As they continue to redefine the boundaries of PCB manufacturing, their impact on the electronic industry becomes increasingly profound, cementing their status as a leading provider of cutting-edge PCB solutions in the Bay Area and beyond.

Efficient Assembly Line Layout Tactics Boost Productivity and Workflow

Assembly Line Layout Revolutionizes Manufacturing Process, Boosting Efficiency and ProductivityIn the competitive world of manufacturing, companies are constantly seeking innovative solutions to enhance their production processes. One groundbreaking approach that has recently gained significant attention is the Assembly Line Layout. This revolutionary concept has the power to transform the manufacturing industry, revolutionizing how products are made and ultimately improving efficiency, productivity, and profitability.Assembly Line Layout, or ALL, is a systematic arrangement of workstations and equipment that allows for a smooth and efficient flow of work from start to finish. It is designed to maximize efficiency by minimizing unnecessary movements, reducing assembly time, and streamlining the entire manufacturing process.By carefully organizing workstations in a sequential order, the Assembly Line Layout eliminates unnecessary backtracking and reduces travel time, resulting in a significant reduction in production time. This arrangement ensures that workers and materials are efficiently utilized and that the production line operates at its maximum potential.With the implementation of ALL, manufacturers can streamline their operations, reduce bottlenecks, and increase overall productivity. By breaking down the production process into smaller tasks, each worker becomes specialized in their assigned task, leading to improved proficiency and speed. This specialization allows for better control over quality, as workers can focus on perfecting their specific task rather than being overwhelmed by multiple responsibilities.One major advantage of the Assembly Line Layout is its scalability. As production demands fluctuate, manufacturers can easily adjust the number of workstations and workers according to their needs. This flexibility allows companies to rapidly adopt changes in demand, ensuring that production keeps pace with market requirements without compromising efficiency or quality.Moreover, the ALL concept promotes standardization, leading to increased product consistency and quality control. With predefined workstations and equipment setups, manufacturers can establish standardized procedures for each task, reducing the risk of human error and ensuring that products meet the highest quality standards. This not only improves customer satisfaction but also reduces costs associated with defective products and rework.The benefits of the Assembly Line Layout extend beyond the manufacturing floor. By optimizing the production process, manufacturers can decrease lead times and deliver products to market faster. This improved time-to-market enables companies to meet customer demands promptly, gain a competitive edge, and capitalize on market opportunities.In addition to the efficiency gains, the Assembly Line Layout facilitates better workflow management. With a clear visual representation of the production process and the ability to monitor progress at each workstation, managers can easily identify bottlenecks and address them proactively. This real-time information empowers decision-makers to make data-driven decisions, optimize resource allocation, and improve overall operational performance.While the Assembly Line Layout offers undeniable advantages, its successful implementation requires careful planning and consideration. Manufacturers must analyze their production requirements, assess the suitability of their product for an assembly line setup, and invest in appropriate equipment and training for their workforce. Additionally, companies must ensure that safety measures are in place to protect workers and prevent accidents in the fast-paced environment of an assembly line.As the manufacturing landscape becomes increasingly competitive, companies must explore innovative solutions to stay ahead. The Assembly Line Layout presents a compelling opportunity for manufacturers to optimize their operations, enhance productivity, and improve profitability. By adopting this revolutionary approach, manufacturers can pave the way for a more efficient and successful future in an ever-evolving industry.

Flexible Circuit Assembly: Benefits and Applications

Flex Circuit Assembly, a leading provider of advanced electronic manufacturing services, is revolutionizing the industry with its cutting-edge technology and innovative solutions. With a strong commitment to quality and customer satisfaction, the company has become a trusted partner for businesses looking to bring their products to market quickly and efficiently.Since its establishment in 1996, Flex Circuit Assembly has continuously expanded its capabilities and expertise. The company specializes in flexible circuit board assembly, offering a wide range of services including design, layout, fabrication, and testing. With advanced manufacturing facilities and state-of-the-art equipment, they are able to meet the diverse needs of their customers across various industries, including automotive, aerospace, consumer electronics, and medical devices.One of the key strengths of Flex Circuit Assembly is their ability to provide customized solutions. Their team of highly skilled engineers works closely with clients to understand their specific requirements and design circuits that not only meet technical specifications, but also optimize performance and reliability. By leveraging their expertise in flexible circuit assembly, they are able to deliver tailored solutions that help clients stay ahead in today's competitive market.Flex Circuit Assembly also prides itself on its commitment to quality. The company adheres to stringent quality control processes at every stage of production, ensuring that every circuit board meets the highest industry standards. Their advanced testing capabilities enable them to thoroughly inspect each piece before it is shipped, guaranteeing that customers receive products of the highest quality and reliability.In addition to their commitment to quality, Flex Circuit Assembly also places great emphasis on customer satisfaction. They understand that each project is unique and requires a personalized approach. By fostering close relationships with their clients, they are able to provide exceptional customer service and support throughout the entire manufacturing process. Whether it is providing design recommendations, offering technical assistance, or facilitating efficient production, the company goes above and beyond to exceed customer expectations.Furthermore, Flex Circuit Assembly is dedicated to environmental sustainability. They employ eco-friendly manufacturing practices, ensuring that their operations have minimal impact on the environment. By utilizing energy-efficient equipment, recycling materials, and adhering to strict waste management protocols, the company strives to minimize their carbon footprint and contribute to a greener future.With their dedication to innovation, quality, customer satisfaction, and sustainability, Flex Circuit Assembly has earned a reputation as a leading player in the electronic manufacturing services industry. Their ability to deliver high-quality, customized solutions has benefited numerous clients, enabling them to bring their products to market faster and more efficiently.Looking ahead, Flex Circuit Assembly plans to further expand its capabilities and technological advancements. They remain committed to staying at the forefront of the industry by investing in research and development, exploring new materials and manufacturing techniques, and continuously improving their processes.As the demand for advanced electronic manufacturing services continues to grow, Flex Circuit Assembly is well-positioned to meet the needs of businesses across various sectors. With their expertise, state-of-the-art facilities, and commitment to excellence, they are poised to make a significant impact in the industry and drive innovation forward.

Revolutionary Circuit Board Home Sparks Innovation and Efficiency

Circuit Board Manufacturer Leads the Way in Sustainable Manufacturing PracticesCircuit Board House (CBH) is a leading manufacturer of printed circuit boards that are used in a wide range of applications, including consumer electronics, automotive industry, computer hardware, and power supplies. The company has been providing high-quality PCB solutions to its clients for over two decades. However, what sets CBH apart from other manufacturers is its commitment to sustainability across all facets of its business operations.CBH understands that as a manufacturer, it has a responsibility to minimize its environmental impact and ensure that its operations are socially responsible. Therefore, the company has taken a proactive approach to addressing these issues by implementing several sustainable practices that reduce waste and improve efficiency.One of the key areas where CBH has made significant strides is in reducing its energy consumption. The company has invested in the installation of energy-efficient equipment and LED lighting in its facilities. This has resulted in a 20% reduction in electricity consumption, cutting the company's carbon footprint by around 1,000 tons per year. The company also recognizes the importance of water conservation and has implemented measures to reduce water usage in its operations.Another significant area of focus for CBH is waste reduction. The company has developed a comprehensive waste management program that includes recycling and reusing as much waste as possible, which has led to a 35% reduction in waste. For example, the company has implemented a strict inventory control system, reducing the amount of scrap material generated during production.In addition to its internal sustainable practices, CBH is committed to sustainable sourcing. The company has established partnerships with suppliers who share its values and who are committed to ethical and environmentally responsible practices. CBH also takes great pride in its employees, providing them with a safe and healthy workplace, along with a range of development and training opportunities.CBH recognizes that its efforts towards sustainability go beyond improving its own operations and extends towards creating a more sustainable industry. Therefore, it is actively engaged in industry associations and initiatives that promote sustainability. The company has also taken a leadership role in educating its clients on the importance of sustainable practices and how they can play a part in creating a more sustainable future.As a result of its commendable efforts, CBH has received several awards and recognitions for its sustainable practices. For example, the company has been awarded the ISO 14001:2015 certification, which acknowledges its commitment to environmental management.Overall, CBH is a company that understands the critical role that businesses play in creating a sustainable future. It has taken admirable steps towards reducing waste, conserving resources, and promoting sustainable practices both within its operations and throughout the broader industry. As the global demand for sustainable practices continues to grow, more companies could learn from CBH's exceptional practices and emulate its approach towards sustainability.

Latest Developments in the Game Console Control Board Industry: What You Need to Know!

Title: Next-Generation Game Console Control Board Unveiled by Prominent Gaming CompanyIntroduction:In a bid to revolutionize the gaming industry, a well-known gaming company has revealed its latest creation - the next-generation game console control board. This state-of-the-art innovation aims to provide gamers with an unparalleled gaming experience, boasting cutting-edge technology and enhanced features. With its sleek design and advanced functionality, this control board promises to redefine the way players interact with their favorite games. Let's dive deeper into the features and potential impact of this groundbreaking invention.1. Enhanced Connectivity and Compatibility:The newly unveiled game console control board ensures seamless connectivity and compatibility across various gaming platforms and devices. Its versatile design supports both wired and wireless connections, allowing gamers the freedom to choose their preferred gaming setup. With its support for the latest Bluetooth technology, players can effortlessly connect the control board to compatible devices, including smartphones and laptops. The control board also integrates with popular gaming consoles, ensuring an immersive gaming experience universally.2. Advanced Precision and Responsiveness:Precision and responsiveness are integral to every gaming experience, and the control board's cutting-edge technology addresses these requirements. Equipped with high-precision analog sticks and pressure-sensitive buttons, this control board offers gamers enhanced control over their actions within games. The increased sensitivity of the control board ensures that players' every movement and action is accurately reflected on-screen, elevating the overall gameplay experience to new heights.3. Customizable Layout and Personalization:Recognizing the diverse preferences of gamers, the game console control board provides extensive customization options. Players can now personalize their control board layout to suit their unique gaming style, offering them a level of comfort and familiarity like never before. The control board allows users to reassign buttons, adjust sensitivity, and even create personalized macros, thus granting players full control over their gaming experience.4. Immersive Audio and Visual Integration:The game console control board incorporates advanced audio and visual integration, enhancing players' gaming immersion. With built-in high-definition audio technology, the control board delivers crisp and realistic sound effects, ensuring players can fully immerse themselves in the game's environment. Furthermore, the control board effortlessly syncs with compatible VR headsets, elevating the player's visual experience to encompass an entirely new dimension of realism.5. Streamlined User Interface and Accessibility Features:The company behind this revolutionary control board understands the value of a streamlined user interface. To enhance user experience, the control board features a user-friendly interface that simplifies navigation and access to various settings. Additionally, the control board integrates accessibility features that cater to gamers with different physical abilities, ensuring inclusivity within the gaming community.Conclusion:The advent of the next-generation game console control board promises to redefine the realms of gaming and create a new era of immersive experiences for gamers worldwide. Its enhanced connectivity, advanced precision, and customizable features allow players to delve deeper into their favorite games with unrivaled control. By integrating cutting-edge audio and visual technologies, the control board ensures an unmatched level of immersion. With its streamlined user interface and accessibility features, the control board caters to a wider audience and fosters inclusivity within the gaming community. As gaming continues to evolve, this groundbreaking control board is set to play a key role in shaping the future of the gaming industry.

Understanding the Key Functions of PCB Boards: A Comprehensive Guide

Title: Pioneering PCB Board Function Revolutionizes Electronics Industry Introduction:A leading electronic manufacturing company, known for its innovation and cutting-edge products, is set to revolutionize the industry with its groundbreaking PCB board function. By incorporating state-of-the-art technology into their circuit boards, the company aims to enhance the performance and efficiency of electronic devices, ultimately transforming the way we interact with these devices.Main Body:1. Understanding the PCB Board Function:PCB, or Printed Circuit Board, acts as the backbone of almost all electronic devices, providing connectivity and support to various components. The primary function of a PCB board is to electrically connect and mechanically support electronic components through conductive tracks, pads, and other features etched from copper sheets laminated onto a non-conductive substrate.2. The Role of PCBs in Technology Advancements:PCB boards have been instrumental in driving technological advancements and miniaturization of devices. Over the years, improvements in manufacturing and design techniques have allowed for increased functionality, reduced power consumption, and greater reliability in electronic devices.3. The Company's Innovative Approach:Building on the foundation of PCB technology, this renowned company has developed a groundbreaking PCB board function that pushes the boundaries of what is achievable in the electronics industry. With a dedicated research and development team, the company has integrated cutting-edge technologies and components into their PCBs to enhance device performance and user experience.4. Enhanced Connectivity and Compatibility:The new PCB board function offers improved connectivity options, allowing for seamless integration with a wider range of devices. This compatibility ensures that electronic devices can communicate efficiently, increasing overall system efficiency and productivity.5. Optimal Power Management:One of the key features of the company's revolutionary PCB board function is its advanced power management capabilities. By optimizing power consumption and regulating voltage levels throughout the device, the technology extends battery life and reduces energy wastage. This not only benefits users by providing longer-lasting devices but also contributes to a greener and more sustainable future.6. Enhanced Processing Speed:Another notable aspect of the new PCB board function is its ability to support high-speed data transfer and processing. By incorporating the latest signal transmission technologies, the company ensures that devices can handle data-intensive tasks with ease. This advancement is particularly beneficial in sectors such as artificial intelligence, virtual reality, and autonomous systems, where processing capabilities are paramount.7. Greater Durability and Reliability:The company's dedicated efforts to enhance the durability and reliability of their products are reflected in their revolutionary PCB board function. Through rigorous testing and quality control measures, the company ensures that their PCBs are robust enough to withstand challenging environments and extreme usage conditions. This reliability not only enhances customer satisfaction but also reduces downtime and maintenance costs.8. Impact on Various Industries:The implementation of the company's revolutionary PCB board function is expected to have a significant impact on numerous industries. From consumer electronics to industrial automation, healthcare to transportation, the improved connectivity, power management, and processing speed will pave the way for innovative applications and improved performance across various sectors.Conclusion: The introduction of this groundbreaking PCB board function represents a significant milestone in the electronics industry. By integrating advanced technologies into their circuit boards, the company is pushing the boundaries of what is possible in terms of device performance, efficiency, and user experience. As a result, electronic devices across various sectors will benefit from enhanced connectivity, optimal power management, faster processing speeds, and increased durability. This significant development not only solidifies the company's position as a pioneer in the industry but also sets the stage for a new era of innovation and advancement.

Essential Guide to Understanding PCB Board Schematic Designs: Simplified & Comprehensive Explanation

PCB Board Schematic – The Way Forward in Electronic ManufacturingThe demand for electronic devices has skyrocketed to an unprecedented level in the last decade. This, in turn, gave rise to the electronic manufacturing industry, which has rapidly evolved to produce high-quality hardware for use in devices such as smartphones, laptops, and televisions, among others.One essential component in the electronic manufacturing process is the Printed Circuit Board (PCB). It is a board that connects and houses electronic components such as capacitors, resistors, and microchips. A PCB comes in various types and is essential in the design of electronic devices.The PCB functions by providing an electrical pathway for the components to connect, communicate, and power each other. It also ensures the stability and durability of the device. To achieve optimal results, every PCB design goes through a process called schematic capture.Schematic capture is the process of creating a blueprint of the PCB design, which is fundamental in ensuring that all the components are in the right position and orientation. This process also makes sure that a particular design meets certain electrical and mechanical specifications.With the importance of schematic capture, PCB Board Schematic (need remove brand name) has become the go-to partner for many electronics manufacturers. They provide high-quality schematic capture services tailored to meet the specific specs of each client. The company is committed to delivering the best PCB services and ensuring that clients achieve their product designs' desired functionalities.The PCB Board Schematic (need remove brand name) company has an experienced team of engineers, designers, and project managers who work tirelessly to ensure that all clients' specifications are met. Their team is highly skilled in both analog and digital electronic designs, and they have a wealth of knowledge in creating schematics for various projects.PCB Board Schematic (need remove brand name) understands the importance of using the latest design software and technology in the electronic industry. They use the latest software such as Altium Designer and CADSTAR to ensure the accuracy and efficiency of the schematic capture process. This approach has not only enabled the company to stay ahead of the competition but also made their services affordable and accessible to clients from all over the world.Besides schematic capture, PCB Board Schematic (need remove brand name) also offers other PCB design services such as routing, manufacturing, and assembly. They have state-of-the-art manufacturing machines that ensure the highest quality, precision, and consistency in all their designs.PCB Board Schematic (need remove brand name)'s success is not only attributed to the quality of their services but also their commitment to customer satisfaction. They value every client and aim to build a long-term and transparent relationship with each one of them.In conclusion, the electronic manufacturing industry is growing each day, and the need for high-quality PCBs is on the rise. PCB Board Schematic (need remove brand name) is committed to providing the best PCB services and ensuring that every client achieves the desired functionalities of their product designs. Their experienced team, use of the latest technology, and commitment to customer satisfaction make them the go-to partner for all your PCB schematic capture and design projects.