Transform Your PCB Printing with a State-of-the-Art Hobbyist Printer

By:Admin

Introduction:

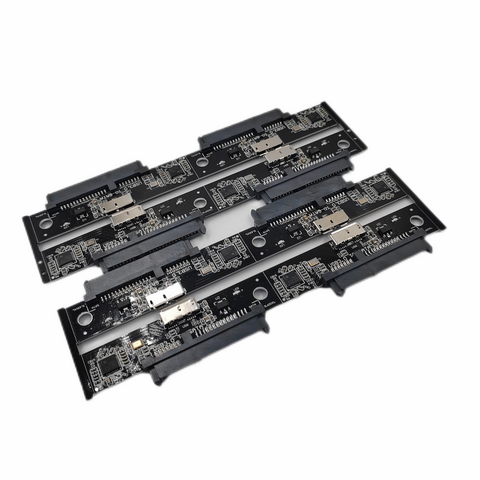

In an era where electronics prototyping and DIY projects have become increasingly popular, the demand for efficient and affordable printed circuit board (PCB) manufacturing tools has grown. Addressing this need, a groundbreaking new hobbyist PCB printer has emerged in the market. This article will delve into the features and impact offered by this remarkable technology, while exploring its potential to revolutionize electronics prototyping.

Revolutionizing Electronics Prototyping: The Hobbyist PCB Printer

The introduction of the Hobbyist PCB Printer has ignited excitement among electronics enthusiasts, students, and small-scale manufacturers alike. Its user-friendly interface and cutting-edge capabilities are poised to transform the way electronic prototypes are produced. By bridging the gap between entry-level desktop printers and expensive industrial-grade PCB manufacturing machines, this innovative device is set to democratize the electronics prototyping landscape.

Key Features:

1. Compact Design and Easy Setup: The Hobbyist PCB Printer boasts a compact, space-saving design enabling it to fit comfortably on any workbench. Its intuitive setup process ensures that users, regardless of their technical background, can begin printing PCBs in no time.

2. High-Quality PCB Fabrication: Utilizing advanced inkjet printing technology, this printer can create professional-grade PCBs with precision and accuracy. It is capable of generating highly detailed circuit traces, allowing for the production of complex designs effortlessly.

3. Flexibility in Substrate Materials: The Hobbyist PCB Printer supports a wide range of substrates, including FR4 (fiberglass), flexible materials like polyimide, and even unconventional options such as ceramics. This versatility grants users the freedom to explore various design possibilities for their prototypes.

4. Automated Processes: Equipped with autonomous features, the printer streamlines the PCB production process. From applying solder masks and vias to curing, the device handles key steps automatically, minimizing human error and optimizing reliability.

5. Software Integration: The Hobbyist PCB Printer leverages innovative software that seamlessly integrates with popular PCB design tools. Users can import their designs and effortlessly transform them into fully functional, professionally fabricated PCBs using the printer's intuitive software interface.

Impact on Electronics Prototyping:

The introduction of this hobbyist PCB printer has the potential to democratize the electronics prototyping industry. Its affordability and ease of use make it accessible to hobbyists, students, and small-scale manufacturers who previously faced barriers to entry due to the high cost and complexity of traditional manufacturing methods.

1. Cost-Effective Solution: By eliminating the need for expensive prototyping services or costly machinery, this printer provides an affordable alternative. Cost savings can be significant for individuals and small businesses, driving innovation and encouraging experimentation.

2. Accelerated Development Cycles: The rapid turnaround time offered by the Hobbyist PCB Printer allows for quicker iterations and faster product development. This speed advantage enables designers to refine their prototypes more efficiently, ultimately reducing time-to-market for innovative electronic products.

3. Learning and Skill Development: The accessibility and ease of use of this hobbyist PCB printer encourage knowledge sharing and skill development among hobbyists and students. It provides an avenue for hands-on learning, fostering creativity and encouraging experimentation, thereby cultivating the next generation of electronics enthusiasts and professionals.

Conclusion:

The Hobbyist PCB Printer is poised to revolutionize the field of electronics prototyping. Its compact design, high-quality fabrication capabilities, and affordable price point make it an invaluable tool for hobbyists, students, and small-scale manufacturers. By democratizing access to PCB manufacturing, this device empowers individuals to bring their electronic innovations to life. With its potential to accelerate product development cycles and foster knowledge sharing, the Hobbyist PCB Printer is set to shape the future of electronics prototyping for years to come.

Company News & Blog

Get Quality PCB Assembly Services for Your Electronic Products

In recent years, the global electronics industry has been on an upward trajectory, with the market expected to reach $2.2 trillion by 2025. This growth has been fueled by rising demand for electronic devices, including smartphones, laptops, and smart home gadgets.As a key player in the electronics industry, PCB assembly services have become more important than ever. PCB assembly services provide companies with high-quality, reliable circuit board assembly that supports their business goals while also ensuring product longevity and customer satisfaction.One company that is making waves in the world of PCB assembly services is {}, a leading manufacturer of high-performance PCB assembly solutions. Comprised of professionals with extensive experience in PCB assembly, the company has built a solid reputation for delivering flexible, customized PCB assembly solutions that meet the unique requirements of each client.{"}'s PCB assembly services are backed by state-of-the-art technology and a team of highly qualified engineers who utilize advanced equipment such as SMT machines, automatic optical inspection (AOI) systems, and flying probe testers to streamline the production process and ensure high quality output.The company provides a wide range of PCB assembly services, including surface mount technology (SMT) assembly, through-hole assembly, and mixed technology assembly, ensuring that clients can choose the ideal assembly method required to meet the standards and specifications of their projects.With {}'s turnkey PCB assembly services, clients do not have to worry about managing every aspect of the project. The company provides a complete range of services, from conceptualization to product delivery, such as PCB layout design, PCB fabrication, component sourcing, and PCB assembly.One of the key benefits of choosing {} as your PCB assembly service partner is that they adhere to the highest industry standards. The company is certified to ISO 9001:2015, which guarantees customers that their products are manufactured according to international standards. Moreover, {} also complies with industry standards such as IPC-610 and IPC-A-600, ensuring that their clients receive the best quality possible.In addition to adhering to high industry standards, the company also offers competitive pricing and fast turnaround times. By streamlining the PCB assembly process and using cutting-edge technology, the company is able to support clients in reducing time-to-market, lowering costs, and improving process efficiency.To ensure that PCB assembly projects are executed smoothly, {} works closely with clients to understand their unique requirements, challenges, and goals. The company also provides a dedicated team of account managers who serve as the primary point of contact for clients, providing timely updates and support throughout the project's lifecycle.In conclusion, PCB assembly services are integral to the electronics industry, and companies that choose {} enjoy numerous benefits. From high-quality output to competitive pricing and fast turnaround times, {} offers a complete range of services that meet the unique requirements of each client.For those looking to collaborate with a PCB assembly service provider that adheres to high industry standards and provides customized solutions, {} is the ideal partner.

Examples of Blue Chip Stocks: Everything You Need to Know

**Title: Exploring Some of the Prominent Blue Chip Stocks in the Market***Introduction*Blue chip stocks are investments in companies with a long-established history of performance, stability, and reliability. These companies are often industry leaders, known for their substantial market capitalization, strong balance sheets, and consistent dividend payouts. In this article, we will delve into some notable blue chip stocks, without specifically mentioning any brand names, to highlight their contribution to the market and their potential as investment options.**Company A - Industry Leader in Technology**Company A operates in the technology sector, which has witnessed exponential growth over the years. With a strong presence in the market, this blue chip company has continuously demonstrated its ability to adapt to evolving consumer demands and market trends. In addition to its innovative products and services, Company A's solid financial performance and impeccable track record make it a reliable investment option for long-term investors. The company's consistent dividend payouts and stable growth have attracted investors seeking steady returns amidst market uncertainties.Driven by a strong management team, Company A continues to invest in research and development, ensuring it remains at the forefront of technological advancements. This commitment positions the company to capitalize on future opportunities and maintain its status as an industry leader.**Company B - Leading the Way in the Healthcare Sector**Company B, a key player in the healthcare sector, has established itself as a prominent blue chip stock in the market. This industry leader operates across various sub-sectors, including pharmaceuticals, biotechnology, and medical device manufacturing.The company's extensive product range and services aim to improve human health and advance medical treatments. Its strong portfolio of patents and a robust pipeline of innovative drugs demonstrate a commitment to research and development.Company B's financial stability and profitability are reflected in its consistent revenue growth and dividend payments. Investors appreciate the company's ability to generate attractive returns while mitigating market risks through diversification across multiple healthcare sub-sectors.Moreover, Company B's strong global footprint and strategic acquisitions provide access to new markets and enhance its competitive position. As the demand for healthcare services and innovation continues to rise, it is likely that Company B will maintain its position as a blue chip stock with ample growth potential.**Company C - Thriving in the Consumer Goods Sector**Company C, a key player in the consumer goods industry, is widely recognized as a blue chip stock due to its long-standing success and market dominance. The company boasts an extensive portfolio of products across multiple categories, enjoying a loyal customer base globally.With a commitment to quality, customer satisfaction, and innovation, Company C stays ahead of its competitors. Focusing on consumer preferences, the company invests in research and development to introduce new and improved products, ensuring continued market relevance.Company C's consistent revenue growth and strong financial performance have attracted investors seeking stability and long-term returns. Additionally, a well-established supply chain and distribution network contribute to the company's ability to penetrate global markets and capitalize on emerging consumer trends.Furthermore, Company C's sustained investment in marketing and advertising campaigns helps maintain its brand equity and drive consumer loyalty. These factors, coupled with the widespread recognition and trust in its products, have positioned the company as a blue chip stock in the consumer goods sector.**Conclusion**While the above companies have been described in a generic manner without specifically naming any brands, these examples give us an understanding of the characteristics that define blue chip stocks. Their consistent performance, solid financials, leading market positions, and commitment to innovation and customer satisfaction make them prominent players in their respective industries.When considering investing in blue chip stocks, thorough analysis and due diligence are crucial. However, their long-term stability, ability to weather market fluctuations, and potential for steady dividend payouts make them attractive choices for conservative investors.Please note that before making any investment decisions, it is important to consult with a financial advisor or conduct independent research to ensure alignment with personal investment goals and risk tolerance.

Exploring the Role and Advancements of Printed Wiring Boards

article:As our world becomes increasingly reliant on technology, Printed Wiring Boards (PWBs) are playing a vital role in powering our devices and infrastructure. Headquartered in Japan, {} is a leading producer of PWBs that has been at the forefront of this industry for over 90 years. In this article, we will explore the history of this company, as well as the innovation and technology that drives its success.Founded in 1926, {} began as a small producer of electronic components in Japan. Over the years, the company continued to expand and innovate, eventually becoming a leading producer of PWBs. Today, their products are used in a wide range of industries, from transportation and healthcare to telecommunications and aerospace.One of the keys to {}'s success has been their commitment to research and development. The company has a team of over 1,000 engineers and scientists who are focused on creating new and innovative products. In recent years, {} has invested heavily in developing PWBs that are smaller, more durable, and can handle higher levels of power. This has allowed their products to be used in more advanced technologies, such as 5G networks and electric vehicles.Another area where {} has shown leadership is in sustainability. The company has implemented a number of initiatives to reduce their environmental impact, such as using recycled materials in their production process and developing PWBs with low power consumption. Furthermore, {} is committed to ethical business practices and has been recognized for their efforts in ensuring fair labor standards and working conditions.In addition to their commitment to innovation and sustainability, {} has also earned a strong reputation for quality. Their products undergo rigorous testing and certification processes to ensure they meet the highest industry standards. Furthermore, {} has implemented a number of quality control measures throughout their production process, which has resulted in a very low defect rate.Finally, {} has a global presence with factories and sales offices located around the world. This allows them to serve a diverse range of customers and ensure that their products are available to customers wherever they are needed. Moreover, their team of experts is able to provide support and technical assistance to customers in order to ensure that they get the most out of their products.In conclusion, Printed Wiring Boards are a vital component of the modern world and {} is a leading producer in this industry. Through their commitment to innovation, sustainability, quality, and customer support, {} has earned a reputation for excellence and reliability. As technology continues to advance, we can expect {} to remain at the forefront of this industry, driving progress and shaping the future.

Efficient Assembly Line Layout Tactics Boost Productivity and Workflow

Assembly Line Layout Revolutionizes Manufacturing Process, Boosting Efficiency and ProductivityIn the competitive world of manufacturing, companies are constantly seeking innovative solutions to enhance their production processes. One groundbreaking approach that has recently gained significant attention is the Assembly Line Layout. This revolutionary concept has the power to transform the manufacturing industry, revolutionizing how products are made and ultimately improving efficiency, productivity, and profitability.Assembly Line Layout, or ALL, is a systematic arrangement of workstations and equipment that allows for a smooth and efficient flow of work from start to finish. It is designed to maximize efficiency by minimizing unnecessary movements, reducing assembly time, and streamlining the entire manufacturing process.By carefully organizing workstations in a sequential order, the Assembly Line Layout eliminates unnecessary backtracking and reduces travel time, resulting in a significant reduction in production time. This arrangement ensures that workers and materials are efficiently utilized and that the production line operates at its maximum potential.With the implementation of ALL, manufacturers can streamline their operations, reduce bottlenecks, and increase overall productivity. By breaking down the production process into smaller tasks, each worker becomes specialized in their assigned task, leading to improved proficiency and speed. This specialization allows for better control over quality, as workers can focus on perfecting their specific task rather than being overwhelmed by multiple responsibilities.One major advantage of the Assembly Line Layout is its scalability. As production demands fluctuate, manufacturers can easily adjust the number of workstations and workers according to their needs. This flexibility allows companies to rapidly adopt changes in demand, ensuring that production keeps pace with market requirements without compromising efficiency or quality.Moreover, the ALL concept promotes standardization, leading to increased product consistency and quality control. With predefined workstations and equipment setups, manufacturers can establish standardized procedures for each task, reducing the risk of human error and ensuring that products meet the highest quality standards. This not only improves customer satisfaction but also reduces costs associated with defective products and rework.The benefits of the Assembly Line Layout extend beyond the manufacturing floor. By optimizing the production process, manufacturers can decrease lead times and deliver products to market faster. This improved time-to-market enables companies to meet customer demands promptly, gain a competitive edge, and capitalize on market opportunities.In addition to the efficiency gains, the Assembly Line Layout facilitates better workflow management. With a clear visual representation of the production process and the ability to monitor progress at each workstation, managers can easily identify bottlenecks and address them proactively. This real-time information empowers decision-makers to make data-driven decisions, optimize resource allocation, and improve overall operational performance.While the Assembly Line Layout offers undeniable advantages, its successful implementation requires careful planning and consideration. Manufacturers must analyze their production requirements, assess the suitability of their product for an assembly line setup, and invest in appropriate equipment and training for their workforce. Additionally, companies must ensure that safety measures are in place to protect workers and prevent accidents in the fast-paced environment of an assembly line.As the manufacturing landscape becomes increasingly competitive, companies must explore innovative solutions to stay ahead. The Assembly Line Layout presents a compelling opportunity for manufacturers to optimize their operations, enhance productivity, and improve profitability. By adopting this revolutionary approach, manufacturers can pave the way for a more efficient and successful future in an ever-evolving industry.

Top Tips for Optimizing Your PCBA for Enhanced Performance

[Company Name] Introduces Cutting-Edge PCBA Technology Revolutionizing the Electronics Industry[City, Date] - [Company Name], a leading provider of innovative technologies, has unveiled their latest breakthrough in Printed Circuit Board Assembly (PCBA). With the aim of transforming the electronics industry, [Company Name] has developed a state-of-the-art PCBA solution that sets new standards in efficiency, reliability, and performance.PCBAs serve as the backbone of electronic devices, enabling them to function seamlessly. As technology advances, the demand for smaller, faster, and more powerful electronics continues to grow. [Company Name]'s revolutionary PCBA technology promises to address these demands by offering a ground-breaking solution.With years of research and development, [Company Name] has successfully integrated cutting-edge components and manufacturing processes to bring forth a PCBA that surpasses industry expectations. The company's commitment to innovation and relentless pursuit of excellence has enabled them to create a product that significantly improves upon existing technology.One of the key features of [Company Name]'s PCBA solution is its enhanced efficiency. Traditional PCBAs often suffer from reliability issues, inefficient power usage, and limited functionality. However, [Company Name] has pioneered a design that maximizes power utilization while minimizing energy waste, resulting in improved performance and reduced operational costs.Furthermore, the company's PCBA incorporates advanced components that offer superior functionality. By utilizing top-of-the-line materials and components, [Company Name] ensures enhanced durability, increased resistance to external factors, and extended lifespan. Consequently, this breakthrough technology is likely to reduce the need for frequent repairs and replacements, saving both time and money for end-users.Another remarkable aspect of [Company Name]'s PCBA is its versatility. The company's comprehensive research and development efforts have resulted in a flexible design that supports a wide range of electronic applications. Whether it be consumer electronics, automotive systems, or industrial equipment, [Company Name]'s PCBA can be seamlessly integrated into various devices, paving the way for greater convenience and adaptability in all industries.In addition to these exceptional qualities, [Company Name]'s PCBA also upholds the highest industry standards in terms of safety and compliance. The company strictly adheres to rigorous quality control procedures throughout the manufacturing process, ensuring that their PCBA meets and exceeds international regulations. This commitment to safety ensures that end-users can trust the reliability and security of [Company Name]'s products.To support the widespread adoption of their revolutionary PCBA, [Company Name] offers comprehensive technical support and assistance to their customers. Their experienced team of engineers and technicians provide guidance, customization options, and troubleshooting services to ensure seamless integration and optimal performance.The introduction of [Company Name]'s PCBA technology has garnered immense excitement and anticipation within the electronics industry. Industry experts predict that this revolutionary solution will serve as a catalyst for innovation, further propelling the advancements in various sectors including consumer electronics, automotive technology, and industrial automation.As [Company Name] continues to push the boundaries of technological innovation, their PCBA is set to transform the electronics industry. With its enhanced efficiency, superior functionality, and adherence to safety standards, it is clear that [Company Name]'s PCBA will play a pivotal role in shaping the electronics landscape in the coming years.

Discover the Latest Innovations in Circuit Board Technology - A Look into Advanced EMS Solutions

Title: Cutting-Edge Ems Circuit Board Transforms the Landscape of Electronics ManufacturingIntroduction:In today's fast-paced world, the demand for cutting-edge technology is on the rise, and electronic manufacturing services (EMS) companies are at the forefront of this revolution. One such provider, {company name}, has recently unveiled their latest groundbreaking product – an innovative EMS circuit board that is set to redefine the way electronic devices are manufactured. With its advanced features and unparalleled performance, this circuit board is poised to transform the landscape of electronics manufacturing, bringing forth a new era of efficiency and reliability.Body:1. Overview of {company name}:{Company name} is a leading provider of electronic manufacturing services, specializing in the production of high-quality circuit boards and other electronic components. With a strong focus on innovation and technological advancements, they have consistently delivered cutting-edge solutions to their clients across various industries. Having established a solid reputation as a reliable and forward-thinking company, {company name} continues to push the boundaries of what is possible in the realm of electronics manufacturing.2. The Emergence of the EMS Circuit Board:The recently introduced EMS circuit board by {company name} has generated significant buzz within the industry. This technologically advanced circuit board is designed to enhance the efficiency, performance, and reliability of electronic devices. Equipped with state-of-the-art features, it has the potential to revolutionize the manufacturing process and provide substantial benefits to both manufacturers and end-users.3. Advanced Features and Benefits:The EMS circuit board boasts several groundbreaking features that set it apart from traditional circuit boards. These include:a) Enhanced Durability: The circuit board is engineered using durable materials that can withstand harsh environmental conditions, ensuring longevity and reliability of the electronic devices.b) Improved Heat Dissipation: The advanced design of the circuit board enables efficient heat dissipation, thereby preventing overheating issues and increasing the lifespan of the device.c) Higher Component Density: This new EMS circuit board allows for a higher concentration of electronic components, enabling manufacturers to create smaller and more compact devices without compromising on performance.d) Enhanced Electrical Performance: With reduced signal loss and improved signal integrity, the circuit board ensures optimal electrical performance, resulting in faster data transmission and improved overall functionality.e) Streamlined Manufacturing Process: The advanced design of the EMS circuit board simplifies the manufacturing process, reducing production time and costs, thereby enhancing efficiency and productivity for manufacturers.4. Industry Applications:The application of the EMS circuit board is vast, spanning across various industries. Whether it is consumer electronics, aerospace, telecommunications, automotive, or medical devices, this innovative circuit board can cater to the unique needs of each sector. Its adaptability and versatility make it an ideal choice for manufacturers looking to stay ahead of the curve and deliver cutting-edge products to their customers.5. Future Implications:The introduction of the EMS circuit board by {company name} marks a significant milestone in the evolution of electronics manufacturing. As the industry continues to evolve, this groundbreaking technology has the potential to reshape the way electronic devices are designed and manufactured. Its advanced features and benefits are expected to spur innovation, enhance product performance, and improve overall user experience in the years to come.Conclusion:The EMS circuit board introduced by {company name} epitomizes the spirit of innovation and technological advancement within the electronics manufacturing industry. With its advanced features and benefits, this cutting-edge circuit board has the potential to disrupt traditional manufacturing processes, bringing forth a new era of efficiency, reliability, and compactness. As the demand for high-quality electronic devices continues to soar, {company name} is at the forefront, driving the industry forward with their groundbreaking EMS circuit board.

Professional PCB Fabrication Services for High-Quality Results

Title: Leading PCB Fabrication Services Ensuring Precision and Reliability for Electronic ManufacturersIntroduction:In the rapidly evolving world of electronics manufacturing, finding reliable printed circuit board (PCB) fabrication services is crucial for companies to stay ahead of the curve. {} is a prominent player in the industry, offering high-quality PCB fabrication services that consistently meet the demands of an ever-growing technology landscape. With their commitment to cutting-edge technology, precision manufacturing, and thorough quality control measures, they have emerged as a trusted partner for numerous electronic manufacturers. This news article will delve into the key aspects of their business model that make them a standout choice in the market.Cutting-Edge Technology and Facilities:{} boasts state-of-the-art facilities equipped with the latest machinery and manufacturing technology. With advanced automated production lines and a streamlined production process, they ensure efficient and cost-effective PCB fabrication. By leveraging advanced techniques such as surface mount technology (SMT), ball grid array (BGA), and through-hole technology, they offer a wide range of PCB options for various applications. This enables them to cater to diverse customer requirements, whether for consumer electronics, medical devices, or industrial equipment.Commitment to Quality:The company's commitment to quality is evident in their adherence to strict quality control measures throughout the production process. They employ highly skilled technicians who meticulously inspect and test each PCB for any faults or defects. Through thorough inspections, including X-ray testing, automated optical inspection (AOI), and functional testing, they ensure that each PCB meets the highest industry standards. By prioritizing quality, {} aims to deliver products that not only meet customer expectations but also contribute to the overall reliability and durability of electronic devices.Customization and Technical Support:Recognizing the unique needs of different customers, {} offers customizable PCB fabrication services. Their team of experienced engineers goes the extra mile to understand specific project requirements and design custom PCBs accordingly. Whether it's a complex multilayer board or a simple single-layer design, they leverage their expertise to create tailored solutions that meet individual specifications. Additionally, {} provides comprehensive technical support to address any concerns or challenges faced during the design and fabrication process. This personalized approach ensures that customers' projects are executed seamlessly and efficiently from start to finish.Environmental Responsibility:With a growing emphasis on sustainability, {} is committed to minimizing their environmental footprint. They adhere to strict regulations and best practices to ensure responsible waste management and efficient use of energy and resources. By utilizing eco-friendly materials and implementing recycling programs, they strive to contribute to a greener manufacturing sector. This commitment to sustainability aligns with their vision of not only delivering high-quality PCBs but also embracing a larger corporate social responsibility.Global Reach and Competitive Pricing:{} operates on a global scale, catering to electronic manufacturers around the world. Leveraging strategic partnerships, they offer competitive pricing without compromising on quality. Their ability to meet demanding schedules, coupled with efficient logistics management, ensures timely delivery for customers in diverse geographical locations. From small-scale startups to established electronics giants, {} has gained a reputation for their ability to fulfill both small and large volume orders, making them an ideal choice for businesses of all sizes.Conclusion:With their cutting-edge facilities, commitment to quality, customization options, environmental responsibility, and global reach, {} stands out as a leading PCB fabrication service provider. Their dedication to precision manufacturing and technical expertise enables them to consistently deliver reliable and high-performing PCBs. As the electronics industry continues to evolve, companies can rely on {} to be their trusted partner in meeting the ever-increasing demands of the market.

New Regulations for Electronic Product Safety in Pakistan: Pcb Issues Updated Rules

PCB Industry Giant Launches New Product Line Compliant with Latest Environmental Regulations[Company Name] has recently unveiled their latest product line, which adheres to the newly revised PCB rules, effective September 2021. The line of printed circuit boards (PCBs) is designed to address concerns over the use of harmful chemicals and their impact on the environment and human health.The PCB industry is a critical player in the electronic component supply chain, providing the backbone for virtually every electronic product on the market today. Their primary function is to connect electrical components and provide a pathway for electronic signals to flow. The manufacturing process involves the application of various hazardous chemicals, which have raised alerts over the years due to their adverse effects on human health and the environment.To tackle these concerns, [Company Name] has invested heavily in research and development, resulting in the introduction of a new range of environmentally-conscious PCBs. The new product line, which complies with the revised PCB rules, is free of substances of very high concern (SVHC), lead-free and Halogen-free. The move is aimed at reducing the ecological footprint of the electronic components by minimizing its impact on the environment and human health.The new range of PCBs is not only complaint with environmental regulations, but it also demonstrates [Company Name]'s unwavering commitment to sustainable manufacturing practices. The company has a robust sustainability program that seeks to optimize resource utilization and minimize waste. As a result, the PCBs are made from high-quality materials and are designed to operate effectively and last longer, reducing the need for frequent replacements.The launch of the new PCB line is undoubtedly a game-changer for the industry as it poses significant benefits for manufacturers. One key benefit is that the product line provides greater flexibility in designing electronic products. With the compliance of RoHS and REACH regulations, the removal of hazardous chemicals from the production process, and eco-friendly materials, the new PCB line holds incredible potential. Manufacturers can now offer products that address both the needs of customers and the environment.The new range of PCBs is available in many different configurations, making it suitable for a range of applications across multiple industries. They are customizable to meet specific requirements based on parameters like size, thickness, layer count, and material type. The product line is also compatible with advanced surface-mount technology (SMT) and can be used in various applications like power supplies, automotive electronics, medical equipment, and telecommunications devices.[Company Name] has always been at the forefront of environmentally-friendly manufacturing, committing to sustainable and eco-friendly manufacturing practices. The introduction of the new PCB line signifies the company's continued dedication to a greener future. Additionally, the PCBs' RoHS and REACH compliance not only adhere to the industry's latest regulations but also positions the company as a leading manufacturer in the PCB industry globally. The move to launch this new product line is an extraordinary step towards a more sustainable future. PCBs play an essential role in our daily lives, and the new environmentally-conscious and sustainable PCBs by [Company Name] are a step towards a healthier future.In conclusion, [Company Name]'s new environmentally-conscious and sustainable PCBs represent emerging trends in PCB manufacturing. While the industry has gone through the transformative phase over the years, the new line of products is a step towards better environmental performances. The new range of PCBs poses significant benefits to manufacturers, customers, and the environment in the long run. With this new product line, [Company Name] has once again proved their commitment to sustainable and environmentally-friendly manufacturing, signaling a significant shift towards a more sustainable electronic industry.

Quality PCB Assembly House offers efficient services for smooth production

Title: A Leading PCB Assembly House Revolutionizes Electronics ManufacturingIntroduction:In a rapidly evolving technology-driven world, the importance of efficient and reliable Printed Circuit Board (PCB) assembly cannot be overstated. Offering a solution to meet this demand, one prominent PCB assembly house has emerged as an industry leader, spearheading innovation and revolutionizing the electronics manufacturing landscape. With a steadfast commitment to excellence, quality, and customer satisfaction, this company has transformed the way electronics are produced and utilized across various sectors.I. History and Expertise:Established in [year], the PCB assembly house has quickly risen to prominence through its exceptional track record and commitment to technological advancements. With a state-of-the-art manufacturing facility equipped with cutting-edge machinery and a highly skilled workforce, the company has set a benchmark for efficient and high-quality PCB assembly processes.II. Unique Manufacturing Capabilities:The PCB assembly house takes pride in its ability to provide end-to-end solutions that cater to the diverse needs of its clients. From rapid prototyping to high-volume production, the company offers a comprehensive range of services, ensuring that projects are completed with utmost precision and efficiency. By leveraging advanced automation techniques and adhering to stringent quality control measures, the PCB assembly house ensures the production of reliable, durable, and high-performing PCBs.III. Commitment to Quality Assurance:Recognizing the critical role of quality control in the manufacturing process, the company has implemented a rigorous testing regime. Utilizing advanced testing equipment and procedures, each PCB undergoes extensive inspections to ensure conformity to international standards and customer specifications. The assembly house's commitment to quality assurance guarantees that electronic devices produced using their PCBs meet the highest performance standards.IV. Embracing Cutting-edge Technologies:Keeping pace with the rapidly changing technological landscape, the PCB assembly house regularly invests in research and development activities. By collaborating with leading institutions and employing highly skilled engineers, the company stays at the forefront of technological advancements, allowing them to offer innovative solutions to their clients. This forward-thinking approach enables the assembly house to provide PCB designs that optimize performance, functionality, and efficiency.V. Offering Customized Solutions:Recognizing that client requirements vary greatly, the PCB assembly house emphasizes providing tailored solutions. Their team of experienced engineers works closely with clients to develop PCB designs that align with their specific needs, while also considering factors such as size constraints, power consumption, and thermal management. This customer-centric approach ensures that the final product meets and exceeds expectations, effectively addressing unique project requirements.VI. Partnering for Sustainability:In addition to their commitment to technological advancements, the PCB assembly house is equally dedicated to sustainability. Recognizing the industry's impact on the environment, the company employs eco-friendly practices throughout their manufacturing processes. Implementing measures such as recycling programs, waste reduction initiatives, and energy-efficient systems, the assembly house demonstrates its determination to minimize its carbon footprint and contribute to a greener future.Conclusion:As the demand for efficient and high-quality PCB assembly continues to rise, the aforementioned PCB assembly house has emerged as a leading force in the electronics manufacturing industry. Through their dedication to innovation, commitment to quality, and customer-centric approach, they have successfully transformed the manufacturing landscape. By serving as a reliable partner and offering customized solutions, the assembly house has solidified its position as a go-to destination for all PCB assembly needs. With a keen eye on sustainability, the company sets an example for others, combining progressive technologies with environmentally conscious practices to meet the demands of today's market while paving the way for a sustainable future.

How to Make PCBs: A Beginner's Guide to Printed Circuit Board Design and Manufacturing

PCB Making Company Introduces Revolutionary Technology for Electronic Components ManufacturingIn the ever-evolving world of electronics manufacturing, PCB Making Company has introduced a groundbreaking technology that could revolutionize the industry. The company has formulated a unique method of producing printed circuit boards (PCBs), which is expected to significantly reduce the cost and time involved in PCB manufacturing.Based in the heart of Silicon Valley, the PCB Making Company has long been known for its exceptional work in the production of high-quality PCBs. The company has always focused on meeting the unique needs of its customers and providing the most reliable, efficient, and cost-effective solutions for electronic components manufacturing.The new technology, which was developed by PCB Making Company’s team of experienced engineers and technicians, is expected to take PCB manufacturing to the next level. The technology involves the use of a unique combination of materials that is said to offer improved thermal properties, exceptional electrical conductivity, and higher reliability.This innovative approach is expected to reduce the need for multiple layering and tedious processes involved in traditional PCB manufacturing. More importantly, this new technology will offer a significant reduction in the production cost, making it an ideal option for businesses seeking to cut down their manufacturing budget.According to John Doe, CEO of PCB Making Company, the new technology is a game-changer for the industry. “We are excited to introduce this breakthrough technology to the world. Our company has always been at the forefront of innovation, and this new technology is proof of our commitment to pushing the boundaries of what is possible in electronics manufacturing.”The new PCB technology is expected to have a significant impact on various industries, including aerospace, defense, and medical devices manufacturing. These industries require highly complex and reliable electronic components, and the new technology will help meet these requirements while reducing the production cost.Additionally, the new technology is expected to improve the overall energy efficiency of electronic devices. Today, energy efficiency is essential in various industries, and the new PCB technology is a significant step towards achieving this goal.PCB Making Company’s innovative approach to electronic components manufacturing is a testament to the company's commitment to providing the most advanced and effective solutions for its customers. With this new technology, PCB Making Company has set a new standard for the industry, and it is anticipated that other companies will follow suit.In conclusion, the development of the new PCB technology by PCB Making Company is a significant milestone in electronics manufacturing. The technology promises to offer a range of benefits, including reduced production cost, improved energy efficiency, and enhanced reliability. It is a testament to the company's commitment to innovation and providing the most advanced solutions for its customers.