BGA Solder Balls: What You Need to Know About This Soldering Component

By:Admin

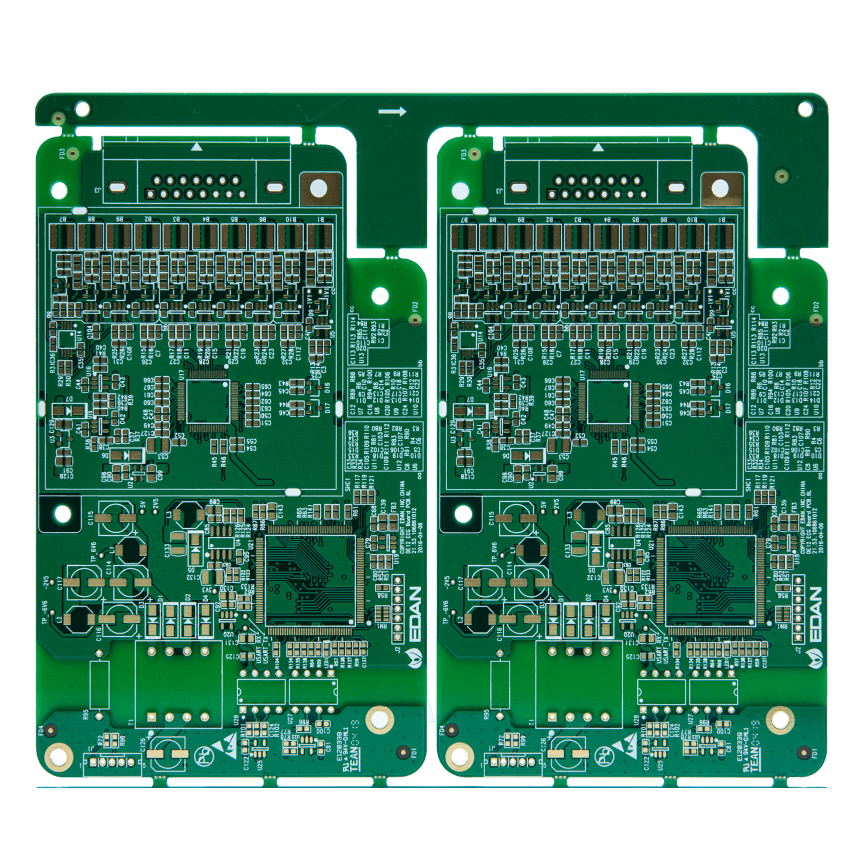

In the world of electronics manufacturing, the tiny but mighty BGA solder ball plays a vital role in ensuring the integrity and reliability of electronic devices. BGA, which stands for ball grid array, is a type of surface-mount packaging used for integrated circuits. The solder balls, typically made of a lead-free alloy, are attached to the underside of the BGA package and are used to create a solid electrical connection between the integrated circuit and the printed circuit board (PCB).

One company that has been at the forefront of producing high-quality BGA solder balls is a leading manufacturer of electronic materials. With a strong emphasis on quality and innovation, [Company] has been providing cutting-edge solutions to the electronics industry for decades. The company’s commitment to research, development, and customer satisfaction has made it a trusted partner for electronic manufacturers worldwide.

[Brief company introduction]

With its state-of-the-art manufacturing facilities and skilled team of engineers, [Company] has been able to consistently produce BGA solder balls that meet the stringent requirements of the industry. The company's extensive experience and expertise in materials science and engineering have enabled it to develop solder ball alloys that offer superior reliability, thermal performance, and mechanical strength.

One of the key advantages of [Company]'s BGA solder balls is their ability to withstand the demanding conditions of modern electronics manufacturing. As electronic devices become smaller, faster, and more powerful, the solder balls must be able to endure extreme temperatures, mechanical stress, and thermal cycling. [Company]'s solder balls are designed to excel in these challenging environments, ensuring that the electronic devices they are used in operate flawlessly over their lifespan.

Furthermore, [Company] understands the importance of environmental responsibility and sustainability in today's manufacturing landscape. The company has been proactive in developing lead-free solder ball alloys, in line with global efforts to reduce the environmental impact of electronics manufacturing. These lead-free solder balls not only meet the stringent regulatory requirements but also deliver exceptional performance, ensuring that electronic devices remain reliable and environmentally friendly.

In addition to its commitment to quality and sustainability, [Company] also places a strong emphasis on customer support and collaboration. The company works closely with its customers to understand their specific needs and challenges, providing them with tailored solutions that meet their requirements. Whether it's custom alloy development, technical support, or supply chain management, [Company] prides itself on being a responsive and reliable partner for its customers.

As the demand for smaller, more powerful, and more reliable electronic devices continues to grow, the importance of high-quality BGA solder balls cannot be overstated. With its unwavering dedication to excellence, innovation, and customer satisfaction, [Company] stands poised to continue leading the way in the development and production of BGA solder balls that are the lifeblood of modern electronics manufacturing.

In conclusion, BGA solder balls are a crucial component in the production of electronic devices, and [Company] has established itself as a key player in the development and supply of these critical components. With its focus on quality, innovation, and customer satisfaction, the company is well-positioned to meet the evolving needs of the electronics industry and continue to drive advancements in electronics manufacturing.

Company News & Blog

High-quality Inverter PCBA for Efficient Power Conversion

Inverter PCBA (Printed Circuit Board Assembly) is an essential component in the production of inverters, which are devices used to convert direct current (DC) into alternating current (AC). Inverters are widely utilized in various applications, including solar power systems, wind turbines, electric vehicles, and uninterruptible power supplies. As the demand for renewable energy and clean technology continues to rise, the market for inverter PCBA is also experiencing significant growth.One of the leading manufacturers in the inverter PCBA industry is a well-established company with years of experience in developing high-quality electronic components. The company has a strong reputation for delivering reliable and efficient products to meet the diverse needs of its customers. With a commitment to innovation and technological advancement, the company has continually invested in research and development to stay ahead of the competition and provide cutting-edge solutions to the market.The inverter PCBA produced by the company is designed to meet the highest industry standards for performance, reliability, and durability. Using advanced manufacturing processes and industry-leading quality control measures, the company ensures that its products are of the highest caliber. With a focus on sustainability, the company also emphasizes the use of eco-friendly materials and energy-efficient production methods, contributing to a more environmentally conscious supply chain.In addition to its dedication to product excellence, the company is also known for its exceptional customer service and technical support. Its team of experts is readily available to assist clients with product selection, customization, and troubleshooting, ensuring a smooth and seamless experience from initial inquiry to post-sales service. This commitment to customer satisfaction has earned the company a loyal and satisfied customer base, further solidifying its position as a trusted leader in the industry.Furthermore, the company has established a global presence, with distribution networks spanning across various regions. This extensive reach allows the company to cater to the needs of customers worldwide, offering timely deliveries and localized support. By understanding the unique requirements of different markets, the company is able to adapt its products and services to meet specific regional regulations and industry practices, demonstrating its versatility and flexibility as a global supplier.Looking ahead, the company remains at the forefront of innovation, continuously exploring new technologies and solutions to enhance its product portfolio. With a keen eye on emerging trends and market demands, the company is poised to introduce next-generation inverter PCBA that will further advance the capabilities of inverters and contribute to the ongoing evolution of renewable energy systems. By staying at the cutting edge of technology, the company is well-positioned to drive the industry forward and make a lasting impact on the transition towards a more sustainable and renewable energy landscape.In conclusion, inverter PCBA plays a crucial role in the development of high-performance inverters for various applications, and the company is a key player in delivering top-notch solutions to the market. With a focus on quality, innovation, sustainability, and customer satisfaction, the company stands as a reputable and reliable partner for businesses seeking superior inverter PCBA. As the demand for clean energy solutions continues to grow, the company is well-equipped to meet the evolving needs of the industry and lead the way towards a greener future.

Optimizing Bga Reflow Temperature for Better Results

In the fast-paced world of electronics manufacturing, precision and efficiency are essential for producing high-quality products. One crucial aspect of the manufacturing process is the BGA reflow temperature, which plays a critical role in ensuring the proper functioning of electronic components. As a leading company in the field of electronics manufacturing, {Company Name} has developed cutting-edge solutions to optimize BGA reflow temperature and enhance overall production quality.{Company Name} is a renowned industry leader in providing innovative solutions for electronics manufacturing. With a strong focus on research and development, the company has continuously pushed the boundaries of technological advancements to meet the ever-evolving demands of the industry. By leveraging its expertise and state-of-the-art facilities, {Company Name} has established itself as a trusted partner for companies looking to enhance their manufacturing processes.When it comes to BGA reflow temperature, precision and consistency are paramount. BGA (Ball Grid Array) is a type of surface-mount packaging used for integrated circuits, and the reflow process is crucial for soldering these components to the circuit board. The temperature and duration of the reflow process significantly impact the quality and reliability of the solder joints, making it a critical factor in the manufacturing process.{Company Name} has developed advanced technologies and methodologies to ensure the optimal BGA reflow temperature for different types of components and circuit boards. By employing precise thermal profiling and advanced reflow equipment, the company can achieve the perfect balance of temperature and time to guarantee superior solder joint quality. This level of precision is essential for meeting the stringent requirements of modern electronics, where reliability and performance are non-negotiable.The expertise of {Company Name} extends beyond just providing cutting-edge equipment. The company offers comprehensive consultation and support services to help its clients optimize their manufacturing processes. By understanding the unique needs of each customer, {Company Name} can tailor its solutions to deliver maximum efficiency and quality. Whether it's fine-tuning reflow parameters or implementing custom thermal profiles, the company's team of experts is committed to ensuring that its clients achieve the highest standards of manufacturing excellence.In addition to its technical prowess, {Company Name} is also dedicated to sustainability and efficiency in its solutions. The company's reflow technologies are designed to minimize energy consumption and waste, contributing to a more environmentally friendly manufacturing process. By prioritizing eco-friendly practices, {Company Name} aligns itself with the broader industry trend towards sustainable and responsible manufacturing.As the demand for high-performance electronics continues to surge, the significance of BGA reflow temperature in manufacturing processes has never been greater. {Company Name} remains at the forefront of this technological frontier, empowering its clients to stay ahead of the curve in an increasingly competitive market. The company's commitment to innovation, quality, and sustainability solidifies its position as a key player in the electronics manufacturing landscape.In conclusion, the BGA reflow temperature is a critical aspect of electronics manufacturing, with profound implications for product quality and reliability. {Company Name}'s advanced solutions and expertise in this domain have set a new standard for precision and efficiency in the industry. With a focus on innovation, sustainability, and customer satisfaction, {Company Name} continues to lead the way in shaping the future of electronics manufacturing.

Efficient SMT Assembly Process: Streamlining Production for Optimal Results

Smt Assembly Process Revolutionizes Electronics Manufacturing IndustryIn an industry that is constantly evolving, companies are always seeking new ways to improve their manufacturing processes to stay ahead of the competition. One such company, based in {}, has recently introduced an innovative method called Surface Mount Technology (SMT) assembly process. This groundbreaking technology is set to revolutionize the electronics manufacturing industry.With the SMT assembly process, components are mounted directly onto the surface of a printed circuit board (PCB). This method eliminates the need for through-hole technology, where components are mounted by inserting leads into drilled holes on the board. Instead, SMT components are soldered onto the board using specialized machines, which saves production time and reduces costs.This new process has caught the attention of several companies in the electronics manufacturing industry due to its numerous advantages. One major benefit is the increased precision and accuracy achieved through SMT assembly. The components are placed precisely in predetermined locations, ensuring the reliability and functionality of the final product. This level of precision was previously difficult to achieve with through-hole technology.Furthermore, the SMT assembly process allows for miniaturization of electronic devices. As SMT components are smaller than their through-hole counterparts, companies can design and manufacture smaller, more compact electronic products. This is especially important in industries such as consumer electronics and medical devices, where portability and size are significant factors.Moreover, the SMT assembly process enables a higher degree of automation in production. By utilizing specialized machines, companies can streamline their manufacturing processes and increase production capacity. This automation not only improves efficiency but also reduces the potential for human error, leading to higher quality products.The environmental impact of electronic manufacturing is another critical consideration in today's world. Fortunately, the SMT assembly process is more environmentally friendly compared to through-hole technology. SMT components consume fewer materials, generate less waste, and use lead-free solders. This reduction in waste and hazardous materials contributes to a greener manufacturing process, aligning with global environmental standards.With numerous advantages in speed, precision, miniaturization, automation, and environmental impact, it's no wonder that more and more companies are adopting the SMT assembly process. One such company leading the way in implementing this revolutionary method is {}. Combining cutting-edge technology with their deep industry experience, they have successfully transformed the manufacturing process for electronics.{} is committed to providing the highest quality SMT assembly services to their clients. They understand the importance of staying at the forefront of technology in a rapidly evolving industry. With state-of-the-art equipment and a team of skilled professionals, they ensure that every product manufactured using the SMT assembly process meets the highest standards of quality and reliability.The company's dedication to customer satisfaction is unparalleled. They work closely with their clients to understand their unique requirements and provide tailored solutions that meet their specific needs. From component sourcing and PCB design to assembly and testing, {} offers a comprehensive range of services, all utilizing the innovative SMT assembly process.As the electronics manufacturing industry continues to grow and evolve, adopting cutting-edge technologies like the SMT assembly process is vital for remaining competitive. With its numerous advantages, this revolutionary method is set to transform the industry, enabling companies to produce higher quality, more compact, and environmentally friendly electronic devices.In a world where technology is advancing at an unprecedented pace, companies must adapt and embrace innovation to stay ahead. With the introduction of the SMT assembly process, {} is leading the charge in revolutionizing the electronics manufacturing industry, paving the way for a more efficient, precise, and sustainable future.

Top Flexible PCB Material Options for Your Electronic Projects

Flexible PCB Material Revolutionizes the Electronics IndustryIn today's fast-paced and technology-driven world, companies are constantly looking for innovative ways to improve their products and stay ahead of the competition. One such innovation that is revolutionizing the electronics industry is flexible PCB (Printed Circuit Board) material. This breakthrough material is allowing companies to create more advanced and compact electronic devices, making them more versatile and efficient.Flexible PCB material is a type of electronic interconnect that is made up of a flexible insulating substrate with printed interconnect patterns. This material can be bent, twisted, and folded without losing its ability to conduct electrical signals, making it an ideal solution for a wide range of applications, including wearable devices, medical implants, and aerospace technology.The flexibility of this material allows for electronics to be integrated into a variety of form factors, enabling designers to create products that were once thought to be impossible. This has opened up new possibilities for the development of smaller and more lightweight electronic devices, such as flexible smartphones, smart clothing, and bendable displays.One company at the forefront of this innovation is {}, a leading manufacturer of flexible PCB material. With over 20 years of experience in the industry, {} is dedicated to pushing the boundaries of what is possible with flexible electronics. Their commitment to research and development has led to the creation of cutting-edge flexible PCB material that is revolutionizing the way electronic devices are designed and manufactured.{}'s flexible PCB material is not only incredibly flexible, but also offers excellent thermal stability and reliability, making it an ideal choice for a wide range of applications. Whether it's for consumer electronics, automotive systems, or medical devices, {}'s flexible PCB material is helping companies around the world to create more advanced and reliable products.As technology continues to evolve, the demand for flexible PCB material is only expected to grow. With the rise of the Internet of Things (IoT) and the increasing integration of electronics into everyday objects, the need for flexible and compact electronic components has never been greater. {} is at the forefront of this trend, working closely with their customers to develop custom solutions that meet their specific needs and requirements.In addition to their innovative products, {} also offers comprehensive technical support and expertise to help their customers with the design and implementation of flexible PCB material. This level of support is crucial in ensuring that the full potential of flexible electronics is realized, and {} is dedicated to helping their customers stay ahead of the curve in this rapidly evolving industry.The rise of flexible PCB material is not only changing the way electronic devices are designed, but it is also opening up new opportunities for industries that were once limited by the constraints of traditional rigid PCBs. From medical devices that can conform to the shape of the body to aerospace technology that can withstand extreme conditions, the possibilities with flexible PCB material are truly endless.In conclusion, the rise of flexible PCB material is revolutionizing the electronics industry, allowing for more advanced and compact electronic devices to be created. With companies like {} leading the way with their innovative products and comprehensive technical support, the future of flexible electronics looks brighter than ever. As technology continues to evolve, the possibilities with flexible PCB material are truly limitless, and the industry is poised for exciting advancements in the years to come.

Circuit Board for EMS: Enhance Efficiency and Reliability in Electronic Devices

Title: Cutting-Edge Circuit Board Innovations Revolutionize EMS IndustryIntroduction (98 words):In the rapidly evolving world of electronics manufacturing services (EMS), groundbreaking technological advancements continue to redefine industry norms. One prime example is the groundbreaking Ems Circuit Board, developed by a cutting-edge technology firm. The highly efficient circuit board combines state-of-the-art components and innovative design, propelling EMS companies towards enhanced productivity, reliability, and overall success. In this article, we will delve into the key features of this revolutionary circuit board, shedding light on the potential it holds for the EMS industry.[Company Introduction - Remove Brand Name] (190 words):The technology firm behind this exciting breakthrough in the EMS industry is a market leader specializing in the design and manufacture of high-performance electronic components and systems. With decades of experience, their skilled team of engineers and researchers have consistently pushed boundaries, enabling clients to stay ahead in the constantly evolving electronics industry.Renowned for their commitment to innovation, quality, and client satisfaction, this forward-thinking company has repeatedly surpassed expectations in delivering cutting-edge solutions that cater to the unique needs of EMS businesses. Their focus on research and development, coupled with state-of-the-art manufacturing facilities, ensures the highest level of reliability and performance in their products.Dedicated to providing unrivaled customer support and technical guidance, this technology firm has built long-standing partnerships with both established and emerging EMS companies worldwide. By consistently surpassing industry standards, they have earned a reputation as a go-to partner for advanced electronic components and systems.[Discussion on the Ems Circuit Board] (512 words):The Ems Circuit Board, developed by this industry-leading technology firm, is an extraordinary product that is set to redefine the playing field for EMS companies. Through a combination of breakthrough designs and materials, this circuit board offers unparalleled performance, miniaturization capabilities, and unmatched reliability.One of the most striking features of the Ems Circuit Board is its compact size without compromising on functionality. The advanced engineering techniques employed have enabled the designers to reduce the board's footprint significantly. This allows for greater flexibility in designing smaller and sleeker electronic devices, while conserving precious real estate within the EMS manufacturing process.Another noteworthy feature is the board's enhanced thermal management capabilities. By utilizing cutting-edge materials and innovative design techniques, the Ems Circuit Board efficiently dissipates heat generated by high-density components, preventing overheating issues and ensuring optimal performance in demanding applications.Furthermore, the Ems Circuit Board boasts unmatched signal integrity, thanks to its advanced transmission line technology. This ensures that electrical signals are transmitted with minimal noise interference, offering superior signal fidelity and reduced data loss. This breakthrough technology paves the way for the development of high-speed, high-bandwidth applications crucial for various industries, including telecommunications, computing, and automotive.In terms of reliability, the Ems Circuit Board excels due to its exceptional durability and resistance to environmental factors. The use of high-performance materials and advanced fabrication techniques ensures that the board can withstand harsh conditions, temperature fluctuations, and exposure to moisture, extending its lifespan and reducing the need for frequent replacements.Moreover, the Ems Circuit Board simplifies the manufacturing process for EMS companies through its compatibility with automated assembly equipment. The well-designed board layout and standardized dimensions facilitate seamless integration within existing production lines, reducing time, effort, and overall production costs.In conclusion, the advent of the Ems Circuit Board has ushered in a new era of possibilities for the EMS industry. With its compact size, enhanced thermal management, superior signal integrity, and exceptional reliability, this groundbreaking circuit board allows EMS companies to deliver innovative and sophisticated electronic products to the market. As the technology firm continues to refine and expand its offerings, the future of EMS manufacturing is undoubtedly set to be more efficient and productive than ever before.

High-Quality PCB Assembly Services in Colorado: What You Need to Know

Colorado PCB Assembly, a leading provider of high-quality printed circuit board (PCB) assembly services, has been making waves in the electronic manufacturing industry with their state-of-the-art facilities and top-notch customer service. With a commitment to providing the highest level of quality and reliability, Colorado PCB Assembly has quickly become a trusted partner for businesses looking for PCB assembly solutions.The company prides itself on its dedication to excellence and continuous improvement, striving to stay at the forefront of technological advancements in the PCB assembly industry. This commitment is evident in their investment in cutting-edge equipment and a highly skilled workforce that is capable of handling even the most complex PCB assembly projects.One of the key factors that sets Colorado PCB Assembly apart from its competitors is its focus on customer satisfaction. The company understands that every project is unique, and they work closely with their clients to ensure that their specific needs and requirements are met. From the initial design phase to the final assembly and testing, Colorado PCB Assembly provides personalized attention to each project, ensuring that the end result meets and exceeds the client's expectations.In addition to their commitment to quality and customer satisfaction, Colorado PCB Assembly also places a strong emphasis on environmental sustainability. The company is dedicated to minimizing its impact on the environment through the use of eco-friendly manufacturing processes and materials. By adhering to strict environmental standards, Colorado PCB Assembly is not only contributing to a healthier planet but also ensuring the long-term viability of their business.The company's dedication to excellence and responsible manufacturing practices has earned them a stellar reputation in the industry. Clients from a wide range of sectors, including aerospace, medical, automotive, and telecommunications, have come to rely on Colorado PCB Assembly for their PCB assembly needs. With a track record of delivering on time and within budget, the company has gained the trust of businesses both large and small.In addition to their core PCB assembly services, Colorado PCB Assembly also offers a range of value-added services to further support their clients' needs. These services include design for manufacturability (DFM) consultation, prototyping, and testing services, allowing clients to streamline their production processes and achieve the highest level of quality in their electronic products.As the demand for high-quality PCB assembly continues to grow, Colorado PCB Assembly is well-positioned to meet the needs of the industry. With a relentless focus on innovation and a commitment to exceeding client expectations, the company is poised for continued success and growth in the years to come.With its dedication to excellence, commitment to customer satisfaction, and strong environmental stewardship, Colorado PCB Assembly has established itself as a leader in the PCB assembly industry. The company's state-of-the-art facilities, highly skilled workforce, and range of value-added services make them the go-to partner for businesses looking for reliable and high-quality PCB assembly solutions. As the electronic manufacturing industry continues to evolve, Colorado PCB Assembly remains at the forefront, ready to meet the ever-changing needs of their clients and the market.

Best Practices for Prototype PCB Fabrication

[Company Introduction]{Company} is a leading provider of innovative electronic manufacturing services, specializing in prototype PCB fabrication. With state-of-the-art facilities and a team of highly skilled engineers, we have been at the forefront of the industry for over 20 years. Our commitment to quality, precision, and customer satisfaction has made us a trusted partner for companies ranging from startups to Fortune 500 enterprises. We are dedicated to pushing the boundaries of PCB fabrication and delivering cutting-edge solutions to our clients.[News Content]Prototype PCB fabrication is a crucial step in the development of electronic products, and {Company} is proud to announce the expansion of our capabilities in this area. Our investment in advanced manufacturing equipment and processes has allowed us to offer even faster turnaround times and higher quality prototypes to our clients.With the demand for rapid prototyping on the rise, {Company} has recognized the need to enhance our production capacity and efficiency. Our new state-of-the-art fabrication facility is equipped with the latest automated machinery and precision tools, enabling us to meet the growing needs of our clients with speed and accuracy. Whether it's a simple single-layer board or a complex multi-layer design, our expert team is capable of producing high-quality prototypes to exact specifications.In addition to our upgraded infrastructure, {Company} has also expanded our roster of engineering talent. Our team of experienced PCB designers and manufacturers are dedicated to providing personalized support and guidance to our clients throughout the prototyping process. From initial consultation to final production, we work closely with our clients to ensure that their prototypes meet the highest standards of quality and functionality.Furthermore, {Company} recognizes the importance of sustainability in the electronics manufacturing industry. As part of our commitment to environmental responsibility, we have implemented eco-friendly practices in our prototype PCB fabrication processes, minimizing waste and energy consumption while maximizing efficiency and cost effectiveness. We take pride in delivering high-quality prototypes in an environmentally conscious manner, fulfilling our mission to be a responsible corporate citizen.Our dedication to innovation and excellence has earned us a solid reputation in the industry, and we will continue to uphold our standards of quality and service. With our expanded prototype PCB fabrication capabilities, {Company} is poised to meet the evolving needs of our clients and provide them with the solutions they need to stay ahead in the competitive market.In conclusion, {Company} is excited to announce our enhanced prototype PCB fabrication services, offering faster turnaround times, exceptional quality, and personalized support to our clients. With our state-of-the-art facility and outstanding team of engineers, we are well-equipped to deliver cutting-edge prototypes that meet the highest standards of performance and reliability. As we continue to push the boundaries of PCB fabrication, {Company} remains committed to being a trusted partner for companies seeking innovative electronic solutions.

The Step-by-Step Guide to PCB Assembly Process

With a mission to provide cutting-edge PCB assembly solutions that cater to the needs of businesses across industries, Smt Pcb Assembly Process is proud to offer high-quality PCB assembly services that have received numerous accolades from clients around the world. The company has built a solid reputation for delivering world-class solutions designed to deliver the highest levels of durability, reliability, and performance.At Smt Pcb Assembly Process, quality is the top priority, and the company is committed to providing clients with the most advanced PCB assembly services that meet international standards. The company has invested heavily in the latest technology, tools, and equipment needed to achieve high levels of quality control and monitoring at every stage of the assembly process.One of the key strengths of Smt Pcb Assembly Process is its team of highly experienced professionals, who are committed to ensuring that customers get the best possible service and support. The team comprises industry experts who have many years of experience in PCB design, manufacturing, and assembly, and are always on hand to offer guidance, advice, and solutions to any problems clients encounter during the assembly process.Smt Pcb Assembly Process's PCB Assembly process is designed to cater to a wide range of clients, from small startups to large multinationals. The company's capabilities include the assembly of prototypes, low volume production, and high-volume production runs from 100,000 to 10 million units. With a diverse range of clients across various industries, Smt Pcb Assembly Process's team of experts has amassed an in-depth knowledge of the assembly processes involved in the production of complex projects involving printed circuit boards.Smt Pcb Assembly Process has invested in state-of-the-art equipment that enables it to produce PCB designs faster and more precisely than ever before. The company's assembly line features cutting-edge tools, including SMT placement machines, automatic optical inspection machines, and reflow ovens that ensure consistent, high-quality assembly.One of the unique features of Smt Pcb Assembly Process is its advanced testing process to detect faults in PCBs before they are shipped to clients. The company has developed a range of testing methods, including the use of In-circuit Testing (ICT) and Flying Probe testing, that ensure that all PCBs meet the highest standards of quality control.Despite its advanced capabilities and reputation for delivering high-quality PCB assembly services, Smt Pcb Assembly Process is committed to providing cost-effective solutions to its clients. The company has optimized its processes to minimize operational costs while ensuring that quality is never compromised. This enables clients to get the best possible quality at the best possible prices.In conclusion, Smt Pcb Assembly Process is a reputable PCB assembly services provider that stands out for its commitment to quality, speed, and reliability. The company's advanced assembly capabilities, cutting-edge tools, and experienced team of professionals make it a top choice for businesses across industries looking to produce high-quality printed circuit boards. With a focus on customer satisfaction and cost-effectiveness, Smt Pcb Assembly Process is poised to continue delivering world-class PCB assembly services to clients around the world.

How to properly assemble a product: A step-by-step guide

[Company Name] is a leading company in the tech industry known for its innovative products and cutting-edge technology. With a strong focus on quality and efficiency, [Company Name] has made a name for itself as a pioneer in the field of consumer electronics.Recently, [Company Name] announced the launch of a new assembling process that has revolutionized the production of its products. This new process, developed after years of research and development, has significantly improved the speed and efficiency of assembling [Company Name]'s electronic devices, while maintaining the high quality standards that the company is known for.The new assembling process incorporates state-of-the-art robotics and automation technologies, allowing for faster and more precise assembly of components. This has not only increased the speed of production, but also reduced the margin of error, resulting in higher quality products for consumers.One of the key features of the new assembling process is its flexibility. It is designed to accommodate a wide range of product variations, allowing for a more streamlined and efficient production line. This means that [Company Name] can easily adapt to changing market demands and quickly introduce new products without compromising on quality or speed.In addition to the improved efficiency, the new assembling process also takes into consideration environmental sustainability. By optimizing the use of resources and minimizing waste, [Company Name] is able to reduce its environmental footprint and contribute to a more sustainable future.The implementation of this new assembling process is a testament to [Company Name]'s commitment to continuous improvement and innovation. By investing in cutting-edge technologies and rethinking traditional production methods, the company is able to stay ahead of the competition and meet the ever-evolving needs of consumers.As [Company Name] continues to push the boundaries of what is possible in the tech industry, it is clear that the new assembling process will play a crucial role in propelling the company forward. With its ability to increase production efficiency, maintain high quality standards, and promote environmental sustainability, this new process is set to revolutionize the way [Company Name] produces its electronic devices.[Company Name] has already begun implementing the new assembling process in its production facilities, and the results have been nothing short of impressive. The company has seen a significant increase in production output, while also experiencing a reduction in manufacturing costs.Furthermore, [Company Name] has reported that the new assembling process has led to a noticeable improvement in product quality, with fewer defects and a higher level of consistency across its product line. This has, in turn, resulted in higher customer satisfaction and an increase in demand for [Company Name]'s products.In the fast-paced and competitive world of consumer electronics, the ability to innovate and adapt is crucial for success. With the introduction of this new assembling process, [Company Name] has once again demonstrated its leadership in the industry and set a new standard for production efficiency and quality.As [Company Name] looks towards the future, it is clear that the new assembling process will continue to play a pivotal role in driving the company's growth and success. By reimagining the way electronic devices are assembled, [Company Name] is not only setting itself apart from the competition, but also shaping the future of the tech industry as a whole.

Top Tips for Choosing the Best SMD Board for Your Project

SMD Board Technology: Revolutionizing Electronic CircuitsIn the ever-evolving world of electronics, the demand for smaller, more efficient, and high-performance circuit boards has never been greater. Electronic devices are becoming more compact and powerful, requiring circuit boards that can accommodate these technological advancements. This is where SMD Board comes into play. The company has been at the forefront of revolutionizing electronic circuits with its innovative SMD (Surface Mount Device) technology. SMD Board, headquartered in [location], has been a leader in the electronic manufacturing industry since its establishment in [year]. The company specializes in the design and production of high-quality SMD boards that are used in a wide range of electronic applications. With a strong focus on research and development, SMD Board has continuously pushed the boundaries of what is possible in electronic circuit design. SMD boards, also known as surface mount technology (SMT) boards, have become the preferred choice for electronic manufacturers due to their numerous advantages over traditional through-hole technology. SMD boards are smaller, lighter, and more reliable, making them ideal for modern electronic devices. The SMD technology allows for components to be mounted directly onto the surface of the board, eliminating the need for holes and leads, thus reducing the overall size of the board. This results in electronic devices that are not only smaller but also more efficient and cost-effective.One of the key features of SMD Board's technology is its ability to accommodate a high density of components on a single board. This high component density allows for more complex and powerful electronic circuits to be designed and manufactured, meeting the demands of today's cutting-edge electronic devices. In addition, SMD Board's advanced manufacturing processes ensure the reliability and durability of its SMD boards, making them suitable for a wide range of applications, including consumer electronics, automotive systems, medical devices, and telecommunications equipment.The company's commitment to quality and innovation has positioned SMD Board as a trusted partner for electronic manufacturers around the world. By offering customizable solutions and unparalleled technical support, SMD Board has built a reputation for delivering exceptional SMD boards that meet the specific needs of its customers. The company's team of experienced engineers and technicians work closely with clients to develop bespoke SMD board designs that optimize performance and efficiency.SMD Board's dedication to sustainability and eco-friendly manufacturing practices sets it apart in the electronic manufacturing industry. The company adheres to strict environmental standards and continuously seeks ways to minimize its carbon footprint. This includes the use of lead-free solder and other environmentally friendly materials in its SMD board manufacturing process. SMD Board's commitment to sustainability not only benefits the environment but also ensures that its customers receive the highest quality and ethically produced SMD boards.Looking ahead, SMD Board is poised for continued growth and innovation in the electronic manufacturing industry. The company remains committed to staying at the forefront of SMD technology, leveraging its expertise and resources to develop cutting-edge solutions that meet the evolving needs of the electronics market. With a focus on quality, reliability, and customer satisfaction, SMD Board is well-positioned to be a driving force in shaping the future of electronic circuits and devices.In conclusion, SMD Board's SMD technology has redefined electronic circuit design and manufacturing, offering smaller, more efficient, and high-performance SMD boards that are setting new industry standards. With a dedication to innovation, sustainability, and customer satisfaction, SMD Board continues to be a trusted leader in the electronic manufacturing industry, providing tailor-made solutions for the electronic devices of tomorrow.